Shikarpur lithic assemblage: New questions regarding Rohri chert blade production

1. The Department of Archaeology and Ancient History, Faculty

of Arts, The Maharaja Sayajirao University of Baroda, Vadodara – 390 002,

Gujarat, India.

Email: Gadekar: doyaldua@gmail.com; Ajithprasad: ajitkarolil@rediffmail.com

2. Department of Archaeology, University of Kerala, Kariavattom Campus,

Thiruvananthapuram – 695 581, Kerala, India. Email: rajeshkeraliyan@yahoo.co.in

Abstract:

Recent excavations at Shikarpur, a fortified Harappan site situated near the Gulf of Kuchchh in Gujarat, Western India, brought to light a large collection of Rohri chert blades. Chert found in the Rohri hill near Sukkur in Sindh, central Pakistan is distinctive and easily identifiable. The wide distribution of standardized Rohri chert blades is often regarded as a testimony to the Harappan efficiency in long distance trade and craft production. The possibility of localized production of Rohri chert blades in Gujarat is often negated due to the constraints of raw-material availability. The absence of Rohri chert working debitage from most of the sites in Gujarat, has lent support to this position. The Shikarpur Rohri blade assemblage however incorporates more than 650 blades, a large fluted blade-core and a few Rohri chert debitage. These have led the excavators to suggest that some of the blades found at Shikarpur were locally produced from raw materials brought to the site from the Rohri hills. Typo-technological features of the Rohri chert assemblage from Shikarpur have been analysed in this background. These along with metrical features of the assemblage are compared with Rohri chert assemblages from other major Harappan sites in the region to check the validity of the proposed ‘limited local production’.

Keywords: Harappan Civilization, Shikarpur, Kachchh, Rohri chert, lithic tools

1. Introduction

1.1. The Site

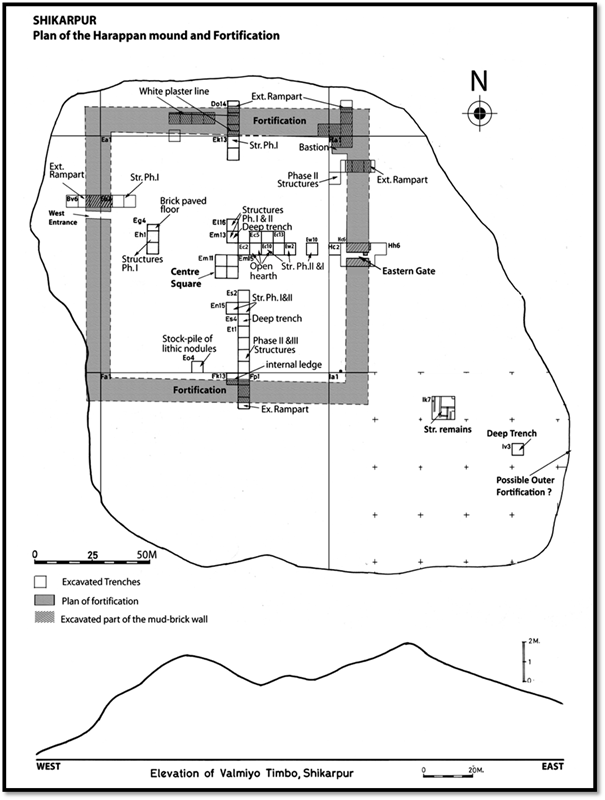

The mound at Shikarpur, known as Valamio Timbo (23o 14’ 15” N; 70o 40’ 39” E) (Figure 1), is a small (approximately 3.4 hectares, see Figure 2) settlement of Urban Harappan Civilization situated near the Gulf of Kachchh in Bhachau Taluka, Kachchh District, Gujarat, India. The site was first excavated by the Gujarat State Archaeology Department during 1987-89. The re-excavations have started here from 2007-2008 field season by the Department of Archaeology and Ancient History, The Maharaja Sayajirao University of Baroda. The main objective of the excavation is to study the overall economic and cultural development of the Harappans in Gujarat in general by investigating the Harappan settlement features and major economic activities followed at this coastal site in particular (Ajithprasad et al., 2012).

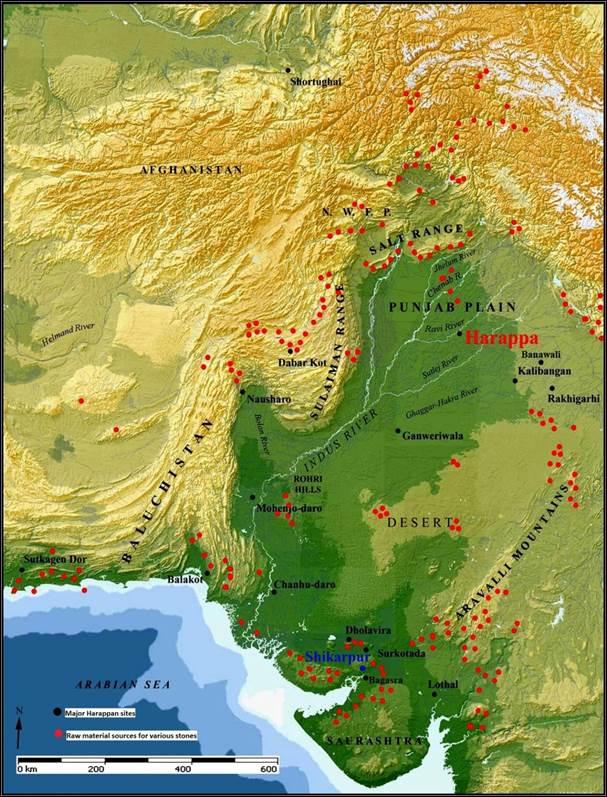

Figure 1. The Rohri hills along with major excavated sites of Harappan civilization. (Image courtesy: Randall Law)

Figure 2. Plan of the Harappan site at Shikarpur showing features of the fortification wall with eastern entrance gate and plan of structures, both inside and outside of the fortified area. (Courtesy: Department of Archaeology and Ancient History, The M.S.U. of Baroda, Vadodara)

Shikarpur has about 6.40m thick overall habitation deposit divisible into three successive Phases of Harappan occupation belonging to the Urban and Post-Urban. The early two Phases - Phases I and II - both belonging to the Urban phase are the most prominently represented cultural remains at the site. These are represented by Classical Harappan artefacts such as stoneware bangles (this is the only site in Gujarat from where these special bangles have been discovered); terracotta objects - beads, bangles, tops (spindle whorls?), human and animal figurines, triangular cakes, toy cart frames and wheels, tablet, sealings or seal impressions; steatite seals; steatite and semi-precious (carnelian, banded agate, variegated chert, lapis lazuli, jasper and amazonite) stone bead; shell objects - bangles, inlay pieces, stylus like cones, pendants and other ornaments; copper objects - knife blades, pointed rods and pins, cobbler’s knife, v-shaped arrow tips, rings, bangles and beads; bone points; a decorated ivory staff and lithic blade tools especially the Rohri chert blades. The remains of Classical Harappan structures made of mud bricks having the standard 1:2:4 ratio are prominent at Shikarpur. The ceramic assemblage includes, apart from the Classical Harappan pottery, good quantities of Anarta pottery, the indigenous ceramic types of North Gujarat and southern Kachchh, suggesting peaceful coexistence of the two traditions.

Phase III deposits belonging to the Post-Urban are patchy and unevenly distributed at the site. They are mostly confined to the eastern and the southern part, have a thickness ranging from 30-50cm and are represented by flimsy circular structures and artefacts (Ajithprasad et al., 2012).

1.2. Rohri Chert

The Rohri hills are situated between the course of Indus River and the cities of Sukkur and Rohri in the north and the Thar Desert in the south in central Pakistan. These limestone formations are 40km long and 16km wide. The hills consist of fossiliferous lime stone rocks of the Brahui formation (Blanford 1877), attributed to the Middle Eocene or Early Oligocene period. They are rich in good quality flint of light brownish-grey colour. Exploitation of this raw material started as early as the Early Palaeolithic times (Biagi & Cremaschi 1998).

The archaeological importance of these quarries (Figure 1) and their association with the Indus Civilization have been pointed out by several scholars (Allchin 1979, Shaikh & Biagi 1997, Biagi 2007:3, Law 2008). Scholars have emphatically pointed out that long distance trade and standardized products characterized lithic assemblage of the Harappan civilization (Inizan & Lechevallier 1995). The wide distribution of standardized Rohri blades is often regarded as an index of the Harappan efficiency in long distance trade and craft production. The distance between the Rohri hills and Shikarpur has been estimated to be somewhere around 500km as the crow flies though the actual trade route must have been much more than that.

2. Objectives

The main objective of this study was to find out the similarities and differences of the Shikarpur lithic assemblage specially of the Rohri chert blades recovered from the site from other assemblages belonging to the same time period. Discovery of a large fluted and a small cylindrical core, several narrow blades, a few primary and secondary crested ridge blades have helped excavators to suggest possible local production of Rohri chert blades. Therefore the second objective was to find out the validity of local manufacturing of Rohri chert tools at Shikarpur.

3. Methods of Study

The lithic assemblage from Shikarpur was analyzed through typological and technological methods. Since this paper deals with the question of Rohri chert blades and its lithic debitage, analysis of only the same is presented here. Tools and lithic debitage of other raw materials have been excluded from this paper. It needs to be pointed out however that Rohri chert blades constitute 89% of all the blades while the Rohri chert lithic debitage is represented at 0.7% of all lithic debitage found from Shikarpur.

The tools were classified into various types of blades and non-geometric tools. Blades have been classified as simple blades (blades without any retouches but with edge damages on their lateral edges), backed blades (blades having retouches along one longitudinal side), strangulated blades (blades with retouch on both the longitudinal sides which gives it the appearance as if notched from both the sides), crested ridge blades, blade flakes (a flake with characteristics of a blade but more thicker and broader) and retouched blades (Blades with minimal and irregular retouches). The non-geometric tools made out of Rohri chert have been classified as points (have a pointed end which is achieved by retouching both the edges of a blade), burin (one side of the pointed end is a result of a vertical blow whereas the other side is made by deliberate notch) and end scraper (retouched at the distal end). Lithic debitage includes flakes (primary as well as secondary), nodules, cores and waste fragments or shatter.

Measurements of tools and debitage were taken by Schlenker digital caliper (SEL-SV-03-150). Attributes recorded for all the tools, broken as well as intact, are the same. These include condition (intact, broken-proximal, mesial, distal), cortex percentages (absent, present- <10%, 10-50%, >50%) edge attributes such as retouches, backings and utilization marks (for both ventral and dorsal side edges separately), condition of polish if present (for both ventral and dorsal side edges separately), description of platforms (proximal end characteristics such as type and shape), condition of distal ends (feathered, plunging, hinged, retouched, snapped, used etc.) and number of dorsal ridges. All the measurements were taken by placing the tools with dorsal side facing the researcher and the proximal end facing up. The lengths correspond to a line perpendicular to the striking platform width; tool widths or breadths were taken at the mid-point of the length, thicknesses were measured by rotating the artefact 900 from the width point. The lateral edges of all the blades were examined macroscopically.

4. Results and discussions

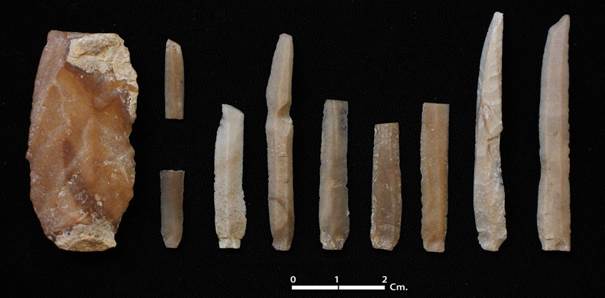

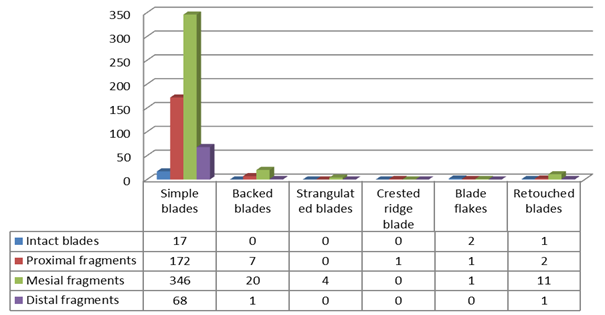

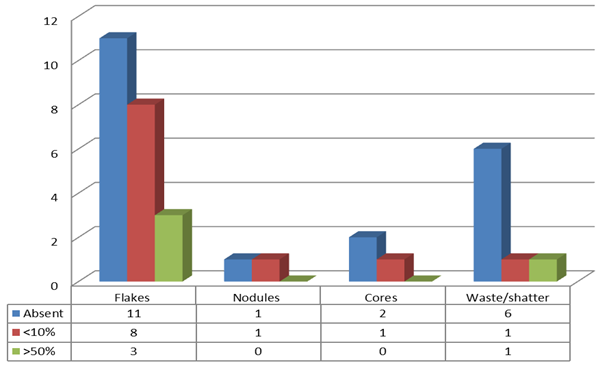

The Rohri chert assemblage recovered from the excavations is represented by 655 blades (Figure 3), 23 geometric and non-geometric tools and 36 fragments of lithic debitage (Figure 4).

Figure 3. Lithic blades from Shikarpur

Figure 4. Lithic Debitage of Rohri chert from Shikarpur

4.1. The blade assemblage

Since majority of the blades were found in fragmentary condition they were further classified according to their fracture into proximal, mesial and distal fragments (Figure 5).

At least 98% blades were found to be devoid of any amount of cortex present on their dorsal surface. It was also seen that most of the time retouched blades were found to be without any cortex. It has been presumed here that most probably secondary blades were selected to manufacture specialized tools. Simple blades and blade flakes do show presence of different categories of cortex, though in very few blades. Since the main bulk of blades came from the Rohri hill quarries, this discrepancy in the presence of cortex is to be expected.

Figure 5: condition of Rohri chert blades

Condition of blade edges: More than 70% blades were found to have use wear, leading to the conclusion that they had been used for some purpose. More than 12% blades showed evidence of retouching: all along one edge, these blades have been classified as backed blades. It was further noticed that more than half of these blades showed retouches on their left edges while the others showed regular retouched on their right edges (tools were analyzes with proximal end and dorsal side of the tool facing up). Irregular retouch on either one or both the edges or presence of notches were observed on 15 blades, 1 was in intact condition while others were broken (2 proximal ends, 11 mesial fragments and 1 distal fragment). Since a majority of the blades were found to be without any retouches it can be assumed that people preferred to utilize blades without first making them into specialized tools. The Rohri chert blades are much broader and thicker than blades of other raw materials and thus it could be possible that no secondary retouches were required on them. It was also noticed that very few blades were left totally blank. Most of the blades were utilized from their dorsal sides. It appears that right edge was more preferred than the left edge (as has been mentioned before, tools were analyzes with proximal end and dorsal side of the tool facing up). Though for bifacial utilization it was seen that left edge of the blade showed more use wear. No retouches were found on the left edge of the blades. Retouches were most common on the dorsal side too. Only about 4% blades showed evidence of polish on their edges.

As we can see maximum numbers of blade fragments belong to the category of mesially broken blades. It was also observed that these blades were clean snapped to break them into fragments. Very few (3.05%) blades were found in intact condition. Proximal blade fragments and distal blade fragments are represented at 27.94% and 10.69% respectively. It was observed that lengths of intact as well as broken blades show high standard deviation values confirming large variation amongst these. Breadth and thickness on the other hand show low values of standard deviation confirming their uniformity in these values (Table 1).

Table 1: metric comparison of Rohri chert blades

|

Rohri chert blades |

No. |

|

Mean |

Median |

Mode |

Std dev |

Variance |

|

Intact blades |

20 |

Length |

47.62 |

42.25 |

24.79 |

21.48 |

461.62 |

|

Breadth |

12.84 |

9.91 |

6.07 |

12.2 |

148.77 |

||

|

Thickness |

3.03 |

2.34 |

1.28 |

2.12 |

4.5 |

||

|

Proximally

broken |

183 |

Length |

33.49 |

31.36 |

34.61 |

15.18 |

230.48 |

|

Breadth |

10.96 |

11.4 |

13.17 |

3.64 |

13.25 |

||

|

Thickness |

2.98 |

2.96 |

2.92 |

1.79 |

3.2 |

||

|

Mesial blades |

382 |

Length |

25.61 |

22.53 |

8.66 |

11.92 |

142.04 |

|

Breadth |

11.52 |

11.63 |

7.53 |

3.13 |

9.82 |

||

|

Thickness |

3.03 |

2.93 |

2.76 |

1.25 |

1.55 |

||

|

Distally

broken |

70 |

Length |

31.18 |

29.45 |

19.82 |

13.72 |

188.16 |

|

Breadth |

10.63 |

11.37 |

10.67 |

2.82 |

7.94 |

||

|

Thickness |

2.86 |

2.77 |

3.16 |

1.46 |

2.12 |

Table 2: Metric comparison of Rohri chert blades (all sizes are in mm)

|

Dholavira 1 |

Banawali 1 |

Bagasra 2 |

Mohenjo-Daro3 |

Indus Valley3 |

Shikarpur |

|||||||||||||||||||||

|

N |

Mean |

Max |

Min |

Sd |

N |

Mean |

Max |

Min |

Sd |

N |

Mean |

Max |

Min |

Sd |

N |

Mean |

Sd |

N |

Mean |

Sd |

N |

Mean |

Max |

Min |

Sd |

|

|

Length |

||||||||||||||||||||||||||

|

proximal |

76 |

28.6 |

91 |

15 |

12 |

93 |

42.4 |

89 |

15 |

17.4 |

32 |

34.6 |

72.7 |

13.4 |

15.1 |

30 |

48.3 |

15 |

583 |

47.7 |

17 |

183 |

33.5 |

79.96 |

4.19 |

15.18 |

|

mesial |

223 |

25.3 |

51 |

13 |

7.5 |

182 |

29.2 |

67 |

8 |

9.5 |

74 |

26.1 |

57.7 |

9.4 |

10.9 |

42 |

36.4 |

11.7 |

642 |

41.6 |

15.9 |

382 |

25.62 |

75.45 |

7.11 |

11.92 |

|

distal |

33 |

29.5 |

78 |

17 |

13.8 |

40 |

37.6 |

77 |

13 |

15.3 |

43 |

31.6 |

70.3 |

10.9 |

12.8 |

23 |

45.9 |

10.3 |

261 |

47.7 |

17.2 |

70 |

31.18 |

77.72 |

9.22 |

13.71 |

|

Width |

||||||||||||||||||||||||||

|

proximal |

76 |

11.6 |

18 |

6 |

2.7 |

93 |

13.3 |

23 |

6 |

11 |

32 |

12.4 |

21.8 |

7.5 |

2.9 |

30 |

13.5 |

3.5 |

583 |

13.5 |

4.1 |

182 |

10.96 |

24.74 |

3.42 |

3.64 |

|

mesial |

233 |

12.2 |

21 |

5 |

2.6 |

182 |

12.9 |

19 |

3.5 |

2.7 |

74 |

11.9 |

26.8 |

6.4 |

3.2 |

42 |

13.1 |

3 |

642 |

13 |

4.1 |

382 |

11.52 |

30.1 |

3.79 |

3.13 |

|

distal |

33 |

11.7 |

19 |

7 |

2.4 |

40 |

11 |

18 |

3.3 |

3.6 |

43 |

11.6 |

17.1 |

4.5 |

3 |

23 |

10.3 |

2.1 |

261 |

13.4 |

5 |

70 |

10.63 |

17.04 |

4.33 |

2.82 |

|

Thickness |

||||||||||||||||||||||||||

|

proximal |

76 |

2.7 |

5 |

1 |

0.8 |

93 |

3.3 |

7 |

1 |

3.3 |

32 |

3.3 |

6.7 |

1.9 |

0.87 |

30 |

3.3 |

1.2 |

583 |

4.1 |

1.3 |

183 |

2.98 |

19.67 |

0.68 |

1.79 |

|

mesial |

233 |

2.8 |

5 |

1 |

0.7 |

182 |

3.1 |

5 |

1 |

1.3 |

74 |

2.9 |

6.8 |

1.4 |

0.9 |

42 |

3.2 |

0.9 |

642 |

3.7 |

1.2 |

382 |

3.03 |

13.11 |

0.09 |

1.25 |

|

distal |

33 |

2.5 |

4 |

1 |

0.9 |

40 |

3.9 |

4.5 |

1 |

0.9 |

43 |

3.2 |

6 |

1.5 |

1 |

23 |

3.6 |

1.7 |

261 |

4 |

1.7 |

70 |

2.86 |

12.64 |

1.06 |

1.46 |

Data for Dholavira, Banawali, Bagasra, Mohenjo-Daro and Indus valley sites has been taken from following sources:

1 Inizan, M.L and M.A.Lechevallier, 1995. Transcultural Phenomena in the Chalcolithic and Bronze Age Lithics of the Old World: Raw Material Circulation and Production of Standardized Long Blades. The Example of the Indus Civilization. In South Asian Archaeology. B. Allchin and F. R. Allchin, (Eds.):77-85.

2 Gadekar, C.S. 2006. A Preliminary Study of the Harappan Blade and Flake Industry of Bagasra. Unpublished M.A. Dissertation. Department of Archaeology and Ancient History, The M.S.University of Baroda, Vadodara.

3 Kenoyer, J.M. 1984. Chipped Stone Tools from Mohenjo-Daro. In Frontiers of Indus Civilization. Lal, B. B. and S.P. Gupta: 117-132.

Inizan and Lechvallier (1995) have proposed that if there is great similarity in the average width of blades (12-14mm) at sites, such widths in parallel edged blades suggest a certain length also. By looking at the ratio of number of mesial to proximal fragments, they have reconstructed blades and have suggested reconstructions for the fractured blades. This exercise was done for data of Rohri chert blades available in various publications and table 2 describes the results. The ratios of mesial:proximal fragments are interesting (table 2). It of course varies between various sites but it can also be seen that the fragments are more in number in sites which are situated further away from the raw material quarries. The ratio was found to be 2.93:1 for Dholavira, 1.95:1 for Banawali, 2.31:1 for Bagasra, 2.08:1 for Shikarpur while 1.4:1 for Mohenjo-Daro and 1.1:1 for other Indus valley sites. By following the reconstruction of blades done by Inizan and Lechvallier (1995) it was clearly seen that the lengths of blades do not vary much between sites situated in the Indus valley or sites situated outside the Indus Valley. The reconstructed length for blade from Banawali comes to be about 14cm [1 proximal (4.6cm), 2 mesial (3.0cm) 1 distal (4.0cm)]; for Dholavira: 13.5cm [1 proximal (3cm), 3 mesial (2.5cm) 1 distal (3cm)]; for Bagasra: 12cm [1 proximal (3.46cm), 2 mesial (2.61cm) 1 distal (3.16cm)]; for Shikarpur 12cm [1 proximal (3.35cm), 2 mesial (2.56cm) 1 distal (3.12cm)]; for Mohenjo-Daro 13cm [1 proximal (4.83cm), 1 mesial (3.64cm) 1 distal (4.59cm)] and for other Indus valley sites 13.7cm [1 proximal (4.77cm), 1 mesial (4.16cm) 1 distal (4.77cm)].

The difference which was observed between these blades was the way they were treated further. Most probably it was not necessary for the sites situated near the Rohri hills to break their blades for better utilization since the Rohri chert quarries were situated nearby and they had easy access to these blades and associated raw material sources. But for the sites situated far outside the Indus valley proper most probably it was necessary to systematically segment these blades in order to standardize these tools and improve their usability on both edges since the quarries were situated so much further. For the same reason long distance trade played a major role in the distribution of these special blades.

4.2. The non-geometric tools

No geometric tools made out of Rohri chert were discovered from Shikarpur. The non‑geometric tools include points (16), burins (6) and end scraper (1). These were made out of Rohri chert blades by further retouching the same.

4.3. The lithic debitage

The lithic debitage of Rohri chert recovered from Shikarpur includes primary (with cortex) and secondary (without cortex) flakes, nodules, cores and shatter or waste fragments. More than half of the lithic debitage was found to have been devoid of cortex (Figure 6). However the presence of cortex on the other half indicates some amount of working of this particular raw material at the site itself.

Figure 6. Distribution of lithic debitage

4.4. Cores

Emphasis has been given on cores since blade cores have been considered formal technologies (Raczek 2007). It has also been suggested that blade cores are portable, efficient and highly suitable for the condition of mobility (Parry 1994, Raczek 2011).

Flint knapping workshops located in the Rohri hills excavated by the Italo-Pakistani expedition have brought to light two different production technologies. The first is related to the debitage of blades from sub-conical and prismatic cores. Flint blades of an average length of 95mm were struck from these cores. These cores were prepared following the crested blade method, and a flat striking platform was obtained by detaching a large flake (Briois et al 2005).

The second production technology was indirect percussion technique which employed a pointed punch. Here initially an almond shaped bifacial pre-from was formed and crested ridge was detached from this. The core pre-form was split into two and adjustments were made for further detachment of blades and then bladelets were struck from these cores by pressure technique. This resulted in the formation of bullet cores. The bladelets removed with this technique were found to have an average length of 45mm (Briois et al 2005).

Two out of the three cores found from Shikarpur belong to the category of blade cores and have been further analyzed. It was found that one is a huge conical core which showed removal of or negative scars of about 11 blades, showed presence of a little cortex on its surface, had a single platform which was achieved by removing a single flake and even showed presence of a little polish on one of the ridges towards the distal end. It measurements showed that it was 116.61mm in length, 37.22mm in breadth, 26.45mm in thickness and weighed 171.6g (Figure 7).

Figure 7. Conical Rohri chert blade core from Shikarpur

The second core is a small cylindrical core. It was found that the platform of this core was in broken condition and blades or flakes were removed in irregular fashion. No cortex was observed on this core and about 5-6 blades were found to have been removed from this core. This core was found to be 50.57mm in length, 24.74mm in breadth, 17.56mm in thickness and weighed 28.47g.

Discovery of both these cores prove that most probably a very limited amount of blade production was carried on at Shikarpur.

5. Conclusions

The presence of a crested guiding ridge blade, 3 cores and a few fragments of lithic debitage with evidence of cortex on some of them has led the archaeologists to form the hypothesis that most probably some amount of onsite production of Rohri chert blades was present at Shikarpur. This type of evidence is generally not found from other Harappan sites in the Gujarat region and thus this has led us to reinvestigate the role played by Shikarpur in the interregional interaction network and exchange of blade tools in the third millennium BC.

Shikarpur has emerged as a very important coastal Harappan site. After six years of excavations the evidence found from this site strongly points towards a society which was very affluent and most probably was actively involved in trade and exchange networks with other Harappan sites. Stratigraphically Shikarpur has not revealed existence of any other culture or community before the Harappan settlement. Thus most probably this place was chosen and a town was established here due to its strategic geographical position. The same has been done at the site of Bagarsa which is situated across the Gulf of Kachchh. Both the sites have yielded evidence of being involved in various craft activities. It has traditionally widely accepted that these Harappan settlements in Gujarat were established as part of concerted colonization of the region undertaken in order to exploit natural recourses such as marine shell and semiprecious stone which were not available in the Indus valley. This model implies that the economies of these Harappan settlements functioned as integral components of an economic system organized at regional level (Bhan and Ajithprasad 2008).

Discovery of so many fragments of Rohri chert blades certainly puts Shikarpur in a category different from the other sites. Such a large number of Rohri chert blades have not been reported, till today, from any other Harappan site in Gujarat. Discovery of these blades which are clearly manufactured in the Rohri hill quarries and were imported to Shikarpur and the few pieces of lithic debitage assemblage recovered from the site forces a lot of questions upon a researcher. Not denying a minor-scale local production of Rohri chert blade manufacturing at the site we would like to propose another hypothesis. Could this be evidence of some merchant –artisan’s efforts, who was trying a small-scale production of Rohri chert blades from raw material brought down from the Indus valley? This kind of occurrence is generally seen in craft production. A lot of time merchants or traders see an exotic or valuable object and they wish to produce the same locally. They bring raw material with them, show finished products and explain the procedure to a craftsman and ask him or her to replicate the product. Was this what was going on at Shikarpur? This challenging puzzle needs to be solved.

Acknowledgements

The authors are thankful to the Department of Archaeology and Ancient History for granting them permission to study lithic assemblage from Shikarpur and to the Department of Archaeology, Gujarat State and Archaeological Survey of India to give permission to excavate the site of Shikarpur. The first author is thankful to the Jawaharlal Nehru Memorial Trust for granting her the Jawaharlal Nehru Scholarship for Doctoral Studies which was the financial backbone of her research. The authors are thankful for the recommendations of referees which have helped to improve the quality of this article. The authors take full responsibility for any remaining shortcomings in the article.

References

Ajithprasad, P., Krishnan, K., Bhan, K.K. and Prathapchandran, S. 2012. Excavations at Shikarpur 2011-2012. Unpublished Excavation report for Archaeological Survey of India, Department of Archaeology and Ancient History, the Maharaja Sayajirao University of Baroda, Vadodara, 43 p.

Allchin, B. 1979. Stone blade industries of early settlements in Sind as indicators of geographical and socio-economical change. In: South Asian Archaeology 1977, (Taddei, M., Ed.), Instituto Universitario Orientale, Naples: p. 173-212.

Bhan, K.K. & Ajithprasad, P. 2008. Excavations at Shikarpur 2007-2008: A coastal port and craft production centre of the Indus civilization in Kutch, India. Accessed: 17 October 2013 URL: http://a.harappa.com/content/excavations-shikarpur-gujarat-2008-2009

Biagi, P. & Starnini, E. 2012. Technological choices and lithic production in the Indus period: case studies from Sindh (Pakistan), Journal of Iranian Archaeology, 2: 21-32.

Biagi, P. & Cremaschi, M. 1988. The early Palaeolithic Sites of the Rohri Hills (Sind, Pakistan) and Their Environmental Significance. World Archaeology, 19(3): 421-433. doi:10.1080/00438243.1988.9980049

Biagi, P. 2007. Quarries in Harappa. In: Encyclopedia of the History of Science, Technology and Medicine in Non-Western Cultures 2, (Selin, H., Ed.), Springer Verlag, Berlin-Heidelberg: p. 1856-1863. doi:10.1007/978-1-4020-4425-0_9696

Blanford, W.T. 1877. Geological notes on the Great Indian Dessert between Sind and Rajputana, Records of the Geological Survey of India, 10(1): 10-21.

Briois, F., Negrino, F., Pelegrin, J. & Starnini, E. 2005. Flint exploitation and blade production during the Harappan period (Bronze Age): testing the evidence from the Rohri Hills flint mines (Sindh-Pakistan) throughout an experimental approach. In: Stone Age-Mining Age, Proceedings of the VIIIth International Flint Symposium, September 13-17 1999, Bochum, (Körlin, G., & Weisgerber, G., Eds.), Veröffentlichungen aus dem Deutschen Bergbaumuseum Bochum 148; Der Anschnitt Beiheft 19. Deutschen Bergbaumuseum, Bochum: p. 185-191.

Gadekar, C.S. 2006. A Preliminary Study of the Harappan Blade and Flake Industry of Bagasra. Master of Arts dissertation no. 215 at the Department of Archaeology and Ancient History, The M.S.University of Baroda, Vadodara, 82 p.

Inizan, M.L & Lechevallier, M.A. 1995. Transcultural Phenomena in the Chalcolithic and Bronze Age Lithics of the Old World: Raw Material Circulation and Production of Standardized Long Blades. The Example of the Indus Civilization. In: South Asian Archaeology. (Allchin, B. & Allchin, F. R., Eds.). Ancient India and Iran Trust, New Delhi: p. 77-85.

Kenoyer, J.M. 1984. Chipped Stone Tools from Mohenjo-Daro. In Frontiers of Indus Civilization, (Lal, B. B. & Gupta, S.P., Eds.), Books and Books, Delhi: p. 171-132.

Law, R. 2008. Inter-Regional Interaction and Urbanism in the Ancient Indus Valley: a Geological Province Study of Harappa's Rock and Mineral Assemblage. Doctoral Dissertation at the Graduate School of University of Wisconsin-Madison, 1148 p.

Parry, W.J. 1994. Prismatic Blade Technologies in North America. In: The Organization of North American Prehistoric Chipped Stone Tool Technology, (Carr, P.J., Ed.), Archaeology Series Vol. 7. International Monographs in Prehistory, Ann Arbor: p. 87-98.

Raczek, T.P. 2007. Shared histories: Technology and community at Gilund and Bagor, Rajasthan, India (c.3000-1700 BC). Doctoral Dissertation at the Department of Anthropology, University of Pennsylvania, 378 p.

Raczek, T.P. 2011. Mobility, Economic Strategies and Social Networks: Investigating Movement in the Mewar Plain. Asian Perspectives 50(1-2): 24-52. doi:10.1353/asi.2011.0008

Shaikh, N & Biagi, P. 1999 The new discoveries on the Rohri hills (1993-1999). Ancient Sindh, 4: 7-17.