Clovis intentional bifacial overshot flaking: Two replica examples

University of Exeter, Department of Archaeology, Laver Building, Exeter UIK EX4 4QE, U.K. Email: b.a.bradley@exeter.ac.uk

Understanding flaking technologies has become an important aspect for flaked stone analyses and interpretations. Experiments are increasingly being used to investigate aspects of technology. One of these aspects is the existence of a technique known as overshot flaking. While most researchers recognize that it happened some assert that it was an intentional technique unique to Solutrean and Clovis archaeological cultures. Others have disputed this assertion and have concluded that it was not a useful technique and therefore unintentional. This small study experimentally examines two reduction sequences that employed intentional overshot flaking and evaluates its usefulness. The conclusion is that it is a useful technique, for a number of reasons, and that it was intentionally employed in some past biface production strategies.

Keywords: Clovis; Solutrean; lithic technology; biface production; overshot flaking; replica

There is an on-going debate as to whether or not ancient knappers used overshot flaking intentionally in the manufacture of bifaces. This has been asserted (Bradley et al. 2010: 68-71), rebutted (Eren et al. 2013: 2934-2941) which itself was challenged (Lohse et al. 2014: 46-64). While this issue may seem to be obscurely technical, the existence (or not) of overshot flaking being systematically employed in reduction strategies has been used as one (of many) criteria to make assertions about historical connections between two separate Palaeolithic archaeological cultures; Solutrean [LGM Basque refugium] and Clovis [Younger Dryas North America] (Stanford & Bradley 2012: 12). The archaeological record speaks to the presence of the use of this technique in Solutrean (Aubry et al. 2008: 58-60) and Clovis (Bradley et al. 2012: 49; Eren et al. 2011 ) (see supplemental information - PFD - DOC) but is this evidence enough to confidently say that the overshot technique was intentional? Eren et al. (2013: 2934-2941) used an experimental method to investigate this question (see Lohse et al. 2014 for a critique of the experiment). Their only focus was on whether or not overshot flaking was an optimal thinning method. Although this was not asserted by Stanford and Bradley (2012), Eren et al. stated that “If Solutrean and Clovis knappers intentionally practiced controlled overshot flaking, they were consciously choosing a technique that is not only difficult to learn and difficult to control but one that provides no additional benefit to, and indeed undermines, the goal of optimally thinning a biface (as defined by Stanford and Bradley, 2012: 49)”. This was a blatant misquote (my emphasis). However, if one considers the additional positive effects of the efficient removal of knapping errors and ‘square’ edges, and other margin issues such as ‘stacks’ (Aubry et al. 2008: 58), the tendency for the result to be longitudinal flattening and regularizing and significant thinning, as well as the production of large useful flakes (Stanford & Bradley 2012: 49; Bradley et al. 2010: 57-60; Smith 1966: 85 [figs. 10.5, 10.9], 92 [figs. 11.4, 11.11], 101 [fig. 14.1]) it seems there are a number of excellent reasons for applying the technique as part of a suit of methods, including ‘full-face’ thinning. So, the relevant question becomes: Is it possible and advantageous to use controlled overshot flaking to the degree that it is an effective method in the reduction of bifaces? In spite of Eren et al.’s (2013: 2940) conclusion that “…Clovis and Solutrean knappers converged on a technique for thinning bifaces that happened to produce the analogous detritus of overshot flakes”, for me, the answer is a resounding “Yes!” It is a method that I, and some other contemporary knappers (academic and amateur) have learned well enough to use intentionally, efficiently and effectively, especially when replicating Solutrean and Clovis biface manufacture.

This is not to say that all overshot attempts are successful nor that mistakes are not made that occasionally lead to failure and abandonment. However, if these circumstances occurred too frequently, it is unlikely that knappers would continue to use the method, at least for reasons of effectiveness or efficiency. Indeed, the training and practice needed to attain a high level of proficiency in overshot flaking, based on personal experience and acknowledged by Eren et al. (2013: 2938), would argue against its adoption and innovation. One could also use the same argument to explain why the method was not innovated in numerous other biface thinning technologies and why it disappeared after Solutrean and Clovis. I contend that the technique itself represented more than simply a way to efficiently make a thin biface. It, along with fluting, may have become a symbolic process that represented risk and its successful application used as a means of representing, possibly reducing, risk in other aspects of peoples’ lives (see Sinclair 1995: 50-62) for a discussion of this for Solutrean and Bradley (1982: 211) for Folsom fluting.

This article presents two examples of controlled overshot flaking describing the intention and results of the removals. This does not ‘prove’ that the method was intentionally used in the past but it does demonstrate that it can be controlled and usefully applied.

Dimensions and proportions of the bifaces are presented in Table 1 and the flakes in Table 2. The terminology used to describe the reduction sequence follows Bradley et al. (2010: 78-79). (See also the supplemental information online - PFD - DOC.)

Table 1. Dimensions and proportions of bifaces before and after flake removals. Abbreviations: os = overshot; ff = full face. L = length; W = width; Th = thickness; Wgt = weight; MR = mass reduction; * all dimensions taken on the flake removal axis.

|

|

|

Dimensions* |

||||||||||

|

|

|

Pre-flake removal |

Post-flake removal |

|||||||||

|

Replica # |

Phase |

L |

W |

Th |

Wgt |

W/Th |

L |

W |

Th |

Wgt |

W/Th |

MR |

|

R1(os) removal 1 |

middle |

141 |

48 |

14 |

113 |

3.4 |

141 |

41 |

10 |

101 |

4.1 |

11% |

|

R2 (os) removal 1 |

early |

183 |

158 |

45 |

1404 |

3.5 |

183 |

132 |

28 |

948 |

4.7 |

32% |

|

R2 (os) removal 2 |

early |

183 |

140 |

33 |

948 |

4.2 |

183 |

129 |

24 |

793 |

5.4 |

16% |

|

R2 (ff) removal 3 |

early |

183 |

123 |

35 |

793 |

3.5 |

121 |

122 |

25 |

717 |

4.9 |

10% |

Table 2. Flake dimensions. Abbreviations: Ld = dorsal length; Lv = ventral length; BWR = biface width reduction (Ld-Lv); W = width Th = thickness; Rt = relative thinning (BWR/Th); Wgt = weight.

|

Flake |

Ld |

Lv |

BWR |

W |

Th |

Rt |

Wgt |

Result |

|

Replica 1 removal 1 (os) |

48 |

45 |

3 |

46 |

8 |

0.38 |

12 |

Removal of cortex’ mass, thinning, flattening. Adjustment of margin into biface plane |

|

Replica 2 removal 1 (os) |

159 |

119 |

40 |

102 |

28 |

1.43 |

456 |

Removal of thick base and margin, thinning and establishment of biface plane |

|

Replica 2 removal 2 (os) |

134 |

128 |

6 |

79 |

14 |

0.43 |

155 |

Removal of cortex and abrupt margin, thinning and flattening |

|

Replica 2 removal 3 (ff) |

116 |

113 |

3 |

69 |

10 |

0.30 |

76 |

Thinning |

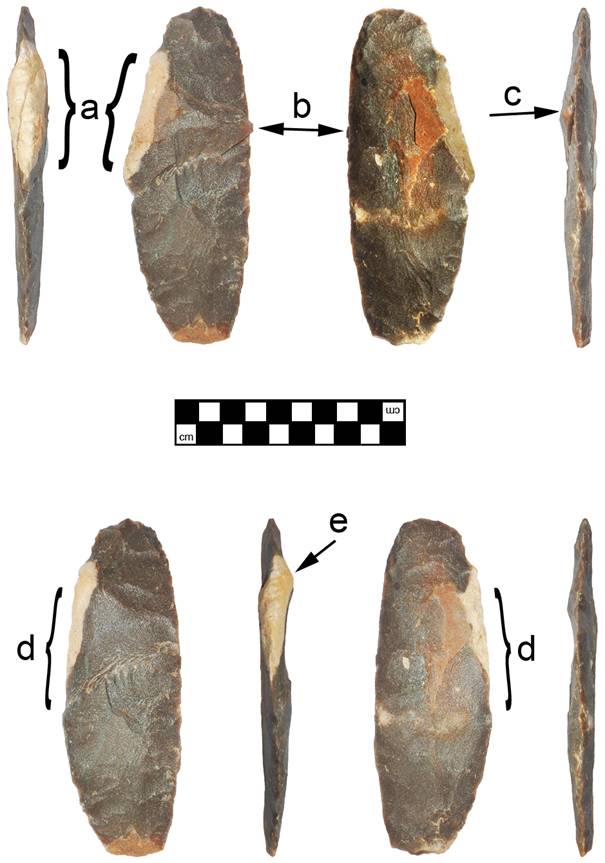

This piece was intended to be made into a projectile point through flaking using a Clovis strategy informed by archaeological examples (see Bradley et al. 2010: 83-91). A flat nodule of local fine-grained silicified sandstone (Grade 3.5 after Whittaker 1994: 66) was selected. The early phase was not recorded as it progressed, however, there were some specific challenges. The greatest was one face and an edge of the natural tabular piece that was covered with an approximately 8 mm thick soft sandy cortex. This made the production of a bifacial edge around the circumference and the removal of invasive thinning flakes difficult. To help reduce the negative effects, much of this cortex was removed by chopping it away with a large hand-held flake. While this allowed the production of a biface, there was still one area of cortex that extended further into the blank (Figure 1a) and it was not easily removed. One option was to reduce the biface length and width and flake the cortex ‘mass’ off along the adjacent margin. This, however was not a preferred Clovis approach. Instead, I removed some more of the cortex by further chopping and when this was no longer effective I resorted to eliminating it with a planned overshot flake removal. This was applied to a middle phase biface (Figure 1 top row).

See Figure 2.

1) to remove a section of heavy cortex from a margin; 2) to flatten the longitudinal section; 3) to relatively thin the biface.

An isolated (Figure 1b) projected (Figure 1c) platform was prepared on the margin

opposite the cortex ‘mass’, lined-up to take advantage of a convex area that ran across the biface to the cortical area. A strong inward blow was delivered with an antler billet producing an overshot flake (Figure 2) that removed a substantial portion of the cortical ‘mass’ (Figure 1d). This was not entirely successful in that part of the cortical ‘mass’ remained (Figure 1e), however the resulting edge was brought into symmetry with the rest of the margin outline near the biface plane.

Figure 1. Replica Clovis middle phase biface with intentional successful overshot flake removal. A) cortex ’mass’ on biface margin; b) isolated platform; c) projected platform; d) area of margin removal; e) remaining cortex ‘mass’.

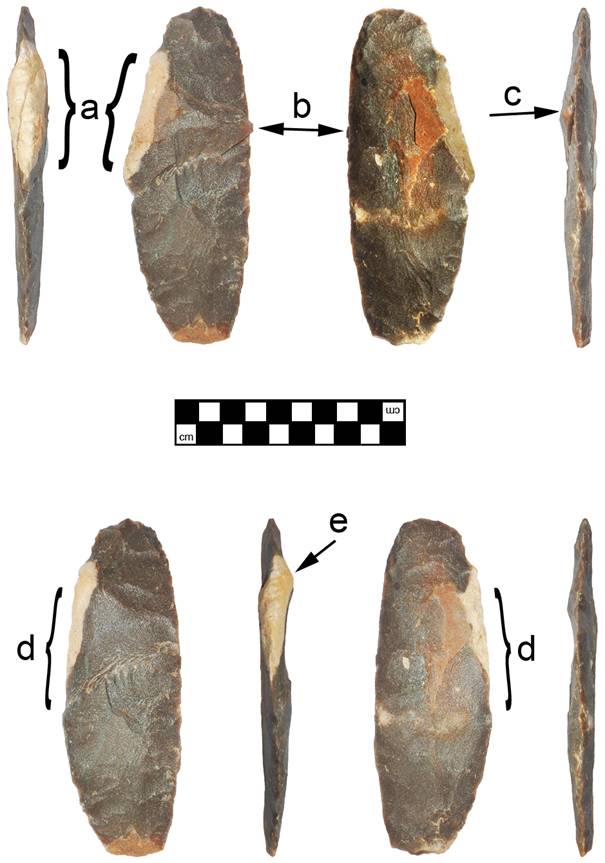

Figure 2. Replica 1 biface overshot flake.

1) a significant portion of the cortex was removed bringing the edge outline into symmetry (Figure 1d); 2) the longitudinal section was flattened but additional flaking is needed to regularize it; and 3) thinning was accomplished. The W:Th ratio along the axis of the removed flake went from 3.4 before removal to 4.1 after removal (see Table 1). While the overshot flake could ideally have removed more of the cortex, it accomplished most of the intended results.

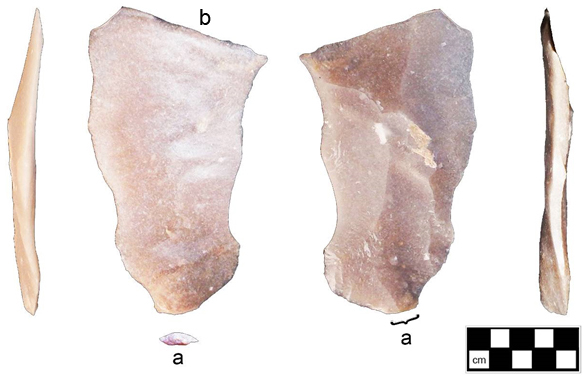

This piece of heat treated (210 ºC) silicified sediment (Grade 2.0) was a roughly rounded tabular form recovered from a shingle beach near Exmouth, Devon, UK and had been rolled in the surf removing any cortex that may have been present on the original piece. The piece was partially flaked at the source to test for flaws. This formed a roughed-out partial, handaxe-like biface blank (Figure 3). The intention of this reduction was to produce a bifacial core for the production of large useable flakes with Clovis attributes. To achieve this, the piece needed to have a bifacial margin around its circumference and to be regularized. The former could have been achieved by using alternating non-invasive flaking, however, the preferred Clovis approach was to remove as many large useful flakes as practical. To this end I chose to remove the base with a large overshot flake.

Figure 3. Replica 2 roughed-out biface blank

See Figure 4.

This flake was intended to remove a large portion of the base of the blank, thinning it without losing length. This was best accomplished by removing an overshot flake, splitting the thick round base. I was not concerned with there being significant width reduction.

Figure 4. Replica 2 Flake 1 overshot flake. A) platform; b) large basal removal; c) removed margin.

I set up a platform at a corner of the base at approximately the projected biface plane. This strong faceted, ground platform (Figure 4a) was struck with a large antler billet with a strong inward and basally angled blow.

Figure 5. Replica 2 biface after overshot removal. a) removed mass; b) overshot flake scar; c) delineated biface plane; d) isolated central area.

A large, thick overshot flake was produced removing a large section of the basal edge (Figure 4b) and a significant portion of the opposite margin (Figure 4c). This thinned the base of the biface (Figure 5a) leaving a large overshot flake scar (Figure 5b). It also defined the biface plane for further flaking (Figure 5c). Even though a large portion of a margin was removed, thinning was accomplished with the W/Th ratio changing from 3.5 to 4.7 (on the axis of the removed flake). This flake removal left a high area running across the biface (Figure 5d) setting up an excellent opportunity for a large useful flake.

See Figure 6.

As the core was well set up for it, a large useful flake was intended, In addition, an overshot removal would flatten the core as well as thin and regularize it, and if well-formed, would bring the opposite margin to the biface plane by the elimination of an abruptly flaked area.

Figure 6. Replica 2 Flake 2 overshot flake. a) prepared platform; b) spacing in relation to previous flake scar; c) margin removed by overshot showing unifacial edge adjustment.

An isolated, slightly projected platform was prepared by faceting, reduction and heavy grinding (Figure 6a). This was located on the margin opposite that from which Flake 1 was struck. Alternating margins is a trait seen on many Clovis bifaces (for example, see Waters & Jennings 2015: 122-123). It was also spaced so that it would only slightly overlap with the previous scar (Figure 6b). In order to encourage the formation of an overshot, the opposite margin was unifacially, abruptly flaked (Figure 6c) so as to bring the edge above the intended biface plane. This assists with the extension of the fracture to the opposite margin (Figure 7a),

Figure 7. Replica 2 biface after removal of second overshot flake. a) overshot termination; b) resulting biface plane; c) platform prepared for the removal of Flake 3 from the other face.

A well-formed overshot flake was produced. It removed the central high area and a portion of the prepared opposite margin. It also flattened and thinned the core from a W/Th ratio of 4.2:1 to 5.4:1. It brought the opposite margin to the biface plane (Figure 7b). Most importantly, it produced a regular useful flake.

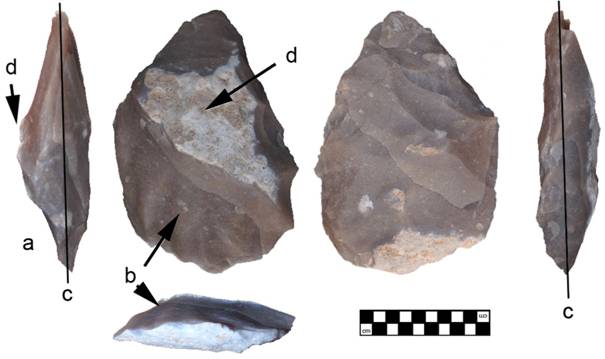

See Figure 8.

Figure 8. Replica 2 Flake 2 full-face flake. a) platform; b) shallow hinge termination.

The goal of this removal was not to thin the biface (core) but to produce a regular, straight, nearly parallel-sided useable flake.

After the removal of the two overshot flakes from the first face a single large full-face thinning flake was removed from the opposite face. A slightly isolated, slightly projected, faceted, reduced and ground (top and front) platform was prepared (Figures 7c and 8a). The flake was struck marginally with an inwardly angled blow. The flake terminated in a shallow hinge fracture. Had the blow been stronger and directed more inward the flake would have overshot, removing a substantial portion of the opposite margin. However, even had this happened, the resulting biface would still have been suitable as a point blank.

This removal produced a regular relatively thin, straight flake (Figure 8) suitable for use as a butchering tool. With unifacial resharpening of one or both lateral margins it would conform to tools recovered from Clovis kill or butchering sites (for examples see Hester 1972: 103 [fig. 93f]; Boldurian & Cotter 1999: 66 [fig. 30]). The resulting core (Figure 9) is typologically and technologically representative of early to middle phase Clovis flake cores (for examples, see Bradley et al. 2010: 60 [fig. 3.4]) and retains the potential for the removal of additional large flake blanks and ultimately could be processed into a Clovis point.

Figure 9. Replica 2 biface core after removal of full-face flake 3 (a).

The direct evidence of overshot flaking is seen on the bifaces in the form of flake scars and on the resulting overshot flakes. As to whether or not the technique was used within a technological strategy needs to be based on the archaeological record. Because, by definition, an overshot flake must remove a portion of an opposite margin, evidence of the method is frequently not present on finished artifacts. In these cases, especially when assemblages are from special function sites, such as hunting camps and kill sites, the technique may, at worst, not be evident or at best, highly under-represented. This is because they were frequently flaked further and the evidence is removed. The presence of the method is best recognized where the archaeological record includes full reduction sequences (or at least early through late phases), pieces broken or discarded during manufacture or caches of unfinished objects. These sites are rare but do exist, such as Gault (Collins 2002), Les Maitreaux (Aubry et al. 2008 ) and a number of well-documented caches such as Fenn (Frison & Bradley 1999) and Hogeye (Waters & Jennings 2015) among many others.

A case for intentional use must be based on a consistent pattern that recurs as part of a recognizable production strategy and it can be demonstrated that the technique was successful in achieving particular goals such as error correction, square edge removal, thinning, flattening, etc. It is not just a matter of documenting presence or absence but in being able to argue that the technique was innovated (see supplemental information - PFD - DOC).

Bradley et al. (2010: 73-75) proposed a method of determining whether or not overshot flakes achieved biface thinning (just one criteria of effectiveness) through a set of measurements and a mathematical formula. While interesting in itself it was only applied to archaeological specimens and this did not demonstrate that it was actually measuring thinning. This approach has been applied to the three experimental samples of overshot flakes included in this study and it is possible to compare the actual results, based on before and after measurements, to those estimated from the flakes (see Table 3). While the flake measurement calculations do seem to indicate thinning (or not) there is not a direct proportional relationship between the results and the actual measured thinning. This is a very small sample and the flake measuring system has not been adequately tested; yet it shows promise.

Table 3. Estimated thinning result based on flake measurements (Bradley et al. 2010:75) compared to measured thinning. Abbreviations: os - overshot; ff - full face; Ld - dorsal length; Lv - ventral length; BWR - biface width reduction; Th - thickness; TI - thinning index; *calculated by dividing “before W/Th” by “after W/Th” and subtracting from 100%; n/a - not available. (See also Tables 1 and 2.)

|

|

|

|

|

|

|

Estimated result |

W/Th change on biface |

||

|

Flake |

Ld |

Lv |

BWR |

Th |

TI |

before |

after |

thinning* |

|

|

Replica 1 removal 1 (os) |

45 |

39 |

6 |

6 |

1.0 |

thinning |

3.4 |

4.1 |

17% |

|

Replica 2 removal 1 (os) |

126 |

99 |

27 |

34 |

0.79 |

thinning |

3.5 |

4.7 |

25% |

|

Replica 1 removal 2 (os) |

124 |

119 |

5 |

13 |

0.38 |

thinning |

4.2 |

5.4 |

22% |

|

Replica 2 removal 3 (ff) |

n/a |

n/a |

n/a |

n/a |

n/a |

n/a |

3.5 |

4.9 |

29% |

This small experiment is an indication of how one might approach understanding the effects of overshot flaking and possible methods of evaluating whether or not it was a controlled, therefore intentional, technique used within biface reduction strategies. It is evident that simplistic assessments, such as only evaluating thinning in relation to optimization, is not adequate on its own. Intentional use of overshot flaking may afford multiple benefits to a knapper, but it also demands high investment, with all of the related social and economic costs, in skill acquisition, The archaeological record seems to show that in most cases this technique was not part of biface thinning strategies, possibly because of the high cost, yet it was innovated by at least two archaeological cultures; Solutrean and Clovis. In these ‘groups’ Stanford and Bradley (2012) suggested that biface flaking represented more value than functional or economic efficiency and may have had symbolic significance The question remains as to whether or not this indicates historical connection; I contend that it does.

Aubry, T., Bradley, B.A., Almeida, M., Walter, B., Neves, M.J., Pelegrin, J., Lenoir, M. & Tiffagom, M. 2008, Solutrean laurel leaf production at Maîtreaux: An experimental approach guided by techno-economic analysis. World Archaeology, 40(1): 48-66. doi:10.1080/00438240701843538

Boldurian, A. & Cotter, J. 1999, Clovis Revisited: New Perspectives on Paleoindian Adaptations from Blackwater Draw, New Mexico. University Museum Monograph Vol. 103. The University Museum, University of Pennsylvania, Philadelphia, 145 p.

Bradley, B. 1982, Lithic technology. In: The Agate Basin site: A record of the Paleoindian occupation of the northwestern High Plains (Frison, G.C. & Stanford, D.J., Eds.), Studies in archaeology, Academic Press, London: p. 181-212.

Bradley, B.A., Collins, M.B. & Hemmings, A.H. 2010, Clovis Technology. Archaeological Series Vol. 17. International Monographs in Prehistory, Ann Arbor, MI, 220 p.

Collins, M. 2002, The Gault Site, Texas, and Clovis Research. Athena Review, 3(2): 24-36.

Eren, M.I., Patten, R.J., O'Brien, M.J. & Meltzer, D.J. 2013, Refuting the technological cornerstone of the Ice-Age Atlantic crossing hypothesis. Journal of Archaeological Science, 40(7): 2934-2941. doi:10.1016/j.jas.2013.02.031

Eren, M.I., Vanderlaan, S. & Holland, J.D. 2011, Overshot Flaking at the Arc Site, Genesee County, New York: Examining the Clovis-Gainey Connection. The Open Anthropology Journal, 4(1): 40-52. doi:10.2174/1874912701104010040

Frison, G. & Bradley, B. 1999, The Fenn Cache: Clovis Weapons & Tools. One Horse Land and Cattle Company, Santa Fe, 111 p.

Hester, J.J. 1972, Blackwater Locality No 1: A Stratified, Early Man Site in Eastern New Mexico. Publication of the Fort Burgwin Research Center Vol. 8. Fort Burgwin Resaearch Center, Southern Methodist University, Ranchos de Taos, NM., 238 p.

Lohse, J.C. 2010, Evidence for Learning and Skill Transmission in Clovis Blade Production and Core Maintenance. In: Clovis Technology (Bradley, B.A., Collins, M.B. & Hemmings, A.H., Eds.), Archaeological Series Vol. 17, International Monographs in Prehistory, Ann Arbor, MI: p. 157-176.

Sinclair, A. 1995, The technique as a symbol in Late Glacial Europe. World Archaeology, 27(1): 50-62. doi:10.1080/00438243.1995.9980292

Smith, P.E.L. 1966, Le Solutréen en France. Imprimeries Delmas, Bordeaux, 449 p.

Stanford, D.J. & Bradley, B.A. 2012, Across Atlantic Ice: The Origin of America’s Clovis Culture. University of California Press, Berkeley, 336 p.

Waters, M.R. & Jennings, T.A. 2015, The Hogeye Clovis Cache. Texas A&M University Press, College Station, Texas, 156 p.