The ground stone industry of the Mursi of Maki, Ethiopia: Ethnoarchaeological research on milling and crushing equipment (technique and function)

École des Hautes Études en Sciences Sociales - EHESS (siège), 190-198 Avenue de France 75244 Paris cedex 13, France. and Laboratoire TRACES UMR5608 Université Toulouse - Jean Jaurès Maison de la Recherche 5, allée Antonio Machado F-31058 Toulouse cedex 9, France. Email: jerome.robitaille@ehess.fr

New ethnoarchaeological evidence is currently contributing to a better understanding of the techniques and functions related to the use of stone tools for grinding and milling. This paper explores how the Mursi people in Maki, Ethiopia use handstones in different ways and how they also use different types of handstones for preparation of a variety of foods. Rather than a pestle and mortar, the Mursi have technically adjusted their tools (querns and handstones) and use them for milling as well as crushing. For example, by using querns for the preparation of grain Mursi women have adapted their techniques and may also use a different handstone (depending on the type of grain they have selected or the final product they wish to prepare). Some handstones are reserved only for crushing grain, others are only for milling, and some have a double function (i.e. they are used for both milling and grinding). (The term “grinding” is used here in terms of the transformation of flour products, while the term “crushing” is used in terms of the transformation of material into pieces.) Is there a connection between the dimensions and the functions of each tool? Can the morphometric characteristics of handstones be related to different types of use? This paper presents new and unpublished ethnographic information showing such a correlation in terms of the Mursi people.

Keywords: ethnography; ground stone tools; morphometry; use-wear; Mursi; Ethiopia

Grinding tools became an important part of material culture used by the first agricultural populations. Even today, the preparation of food by using grinding tools is one of the most important activities of everyday life for woman of the traditional populations of Ethiopia. Cereals are an essential part of their diet and the preparation thereof plays an incontestable role in domestic activities and the distribution of household tasks amongst women (David 1998). This practice of processing cereals is at the centre of social life, daily life, and the economy.

The study of querns and handstones, often well-preserved material in the archaeological record, provides means for us to address the techniques and functions involved in different tasks. It is possible that querns and handstones may have had other technical uses, including treatment of material other than cereals. Querns and handstones could also be used in the treatment of plant materials (condiments, vegetables and legumes, dried fruits, etc.), animal material (dried meat, fish, etc.), or inorganic materials (clay tribulation or pulverising various dyes, etc.). As a first step, however, such an approach requires the functional identification of ground stone tools. Due to the limitations of current knowledge and the unique context, archaeologists frequently have difficulty identifying the functions of the ground stone material found at ancient sites. The study of these objects in an ethnographic or experimental context may offer criteria for the identification of the types of tools and their functions. From an experimental point of view, the technical and functional analysis of the quern has experienced two decades of addressing significant elements of the understanding of subsistence economies and the social organisation of prehistoric populations (e.g., Mauldin 1993; Wright 1994; Fullagar and Field 1997; Adams 1999; de Beaune 2000; Wright 2000; Dubreuil 2002; González and Ibañez 2002; Risch 2002; Delgado-Raack 2008; Hamon and Plisson 2008). Ethnoarchaeological research, however, remains very limited (e.g., Roux 1986; David 1998; Baudais and Lundström-Baudais 2002; Gelbert 2002; Searcy 2011; Rodríguez 2013). This ethnographic research aims to enrich the corpus of reference and the theoretical models that are available to archaeologists in terms of the study of the ground stone used by the Mursi community in Maki, Ethiopia.

It has been over 20 years since F. Sigaut (1991) proposed that systematic analysis should consist of the study of: “structure”, “operation”, and “function”. His conception of objects aimed to avoid the frequent confusion between the “mode of action” (“mode d’action”) of an object and the entire range of all functions (“l’ensemble des finalités”) for which a tool is used. This approach not only offers the means for interpreting reductive associations between form and function, but also invites the theoretical placement of an object within its technical framework.

The distinction between structure, use, and functionality forces, in effect, the systematic analysis of a tool in relation to the modes of action on the material (Leroi-Gourhan 1971) and the objectives for which it was made. This is a straightforward and robust analytical framework for the functional analysis of macro-lithic tools. Thanks to this system, individuals come into the scene of analysis because of the way in which they operate the tool. Similarly, the objective of the operation of the tool is part of the representations associated therewith. This research seeks to establish a link between the intrinsic characteristics of the tools (observable through the use of archaeological evidence) and extrinsic functional data that has been analysed in ethnographic terms.

The ethnographic observations include social and technical components. With regards to the social aspects, surveys focused on: (1) the identity of the artisans (age, gender, social status); (2) the procedure for the transmission and dissemination of knowledge (methods of teaching and the appropriate age for learning); (3) the economy of the activity (organisation of work, seasonal movement); (4) the symbolic context in which the activity fits and interpretations of the tool. Even though this social data is central in terms of the interpretation of the technical variability of the tools, it is not as concerned with the reconstruction of the technical characteristics of the tools, which are presented here. With regards to the technical component, it was important firstly to identify the structure (i.e. the intrinsic characteristics of the tools). The intrinsic characteristics of an object include, on the one hand, (1) its “initial properties”: the properties of the raw material and the dimensions of length, width, and height, which allow for a definition of the volume in which the tool fits; and (2) its “modified properties” - from an ethnographic point of view, some idea of the cycle, duration, and complexity of use can be obtained: the shape and the dimensions of the tool’s working surface and the use-wear associated with the different functions of the tool.

Extrinsic characteristics that were ascertained during investigations relate to (1) the type of the treated plant species; (2) the description of actions; and (3) the identification of the range of functions for each type of tool, while also examining the possible specialisation or versatility. My visits to several households served to identify the activities that are practised with the use of ground stone tools and to verify interactions between the morphology of the tool and the modes of their management (maintenance, re-use, or multi-function).

I collected the ethnographic data used in this work during two expeditions in the region of Maki, Ethiopia (2011 and 2014). In Maki, I examined a total of 60 tools which consisted of equipment for milling and crushing: 30 querns, 26 handstones and four unfinished querns. All were made of granite, recently selected and were in the process of being shaped. These tools come from different hamlets which I visited with the assistance of a local guide, who acted also as an interpreter. Each hamlet is composed of between four and seven families. In general, each family has one or two children.

On my arrival at each hamlet, the guide would explain to the women the purpose of my research and would arrange for me to visit their work areas. There, I measured and registered the dimensions of the tools. I also took negatives of the active surface of the tools (using acetate material) for further examination under a metallographic microscope (which took place in the laboratory of La Maison de la Recherche at the University of Toulouse). In addition to these samples, I took pictures of the active surface of the stones on site, using a Canon Rebel T2i camera, with a macro lens of EFS 60 mm, which allows for up to 15x magnification. Some of these pictures are presented in this work. I also took pictures of the stone tools and of the women using them. For this purpose, I used a Canon Rebel T2i camera. I also recorded short videos of the women using the stone, which I watched repeatedly off-site in order to determine the kinematics involved in these tasks.

While on site, with the assistance of my guide, I extensively interviewed the women of the hamlets, whose stone tools I was allowed to examine. I collected information on how they used their tools, how often they sharpened them, for how long they had used them, and for how long they expected to use them, and what kind of food they process on them and how. All of this ethnographic information was collected with the aim of a functional analysis of stone tools combining use-wear analysis and morphometric data. It enhances our understanding of stone tools and creates a database for comparative analysis with archaeological evidence (i.e. stone tools found on ancient sites).

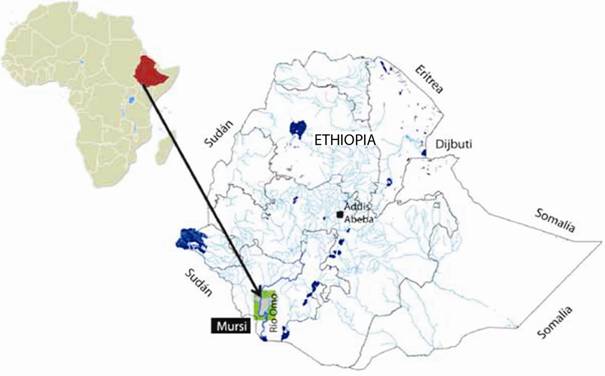

The Mursi are one of many agro-pastoral groups that live in south-west Ethiopia. The Mursi live in a territory of approximately 2,000 km2 located between the Omo River to the west and south, the Mago River to the east, and bordered by the Mara River to the north (Figure 1).

The Mursi depend on three main activities for subsistence: cultivation of flood land, rain-fed agriculture, and pastoralism (mainly cattle). Agriculture represents more than 75% of their diet. Livestock, although an important source of milk (especially for children) and meat, is essential as a reserve in the event of a poor harvest so that it can be exchanged for grain (Turton 1973). The Mursi of Maki use agricultural land along both shores of the Maki River and in the upper Valley of Mago (Mago National Park). They also use pasture land in the Valley of Elma, which is also south of Mago National Park. Women are primarily responsible for agriculture, while the men look after the cattle.

Figure 1. Localisation of the Mursi area in the Omo Valley (after Salazar et al. 2012: 381).

The main crop is sorghum (Sorghum Bicolor (Linn.) Moench) (of which the Mursi have several drought-resistant varieties) and corn (Zea Maysl). They also grow beans and peas (Vigna ifnguiculata (l.) Walp. and Vigna Radiata (l.) Wilczek), gourds (Lagenaria Siceraria (Molina) Standiey) and squash (Cucurbita Maxima Lam.). Wheat, which is consumed in Maki during bad crop seasons, comes from exchange or humanitarian organisations.

Due to the relatively low number of livestock, as well as local rainfall and the unpredictable fluctuation of the annual flood level of Omo River, the Mursi must integrate all three sources of livelihood through a complex cycle of seasonal movements. The Mursi have developed a form of transhumance, which does not allow for any segment of the population to remain fixed in a single locality, although it does take place in a relatively small area. This mixture of subsistence activities and the seasonal dispersion of people and livestock have formed a critical factor for the survival of the Mursi people.

My surveys indicate that the tools were manufactured exclusively by women from a block of granite with a specific morphology. The Mursi of Maki do not seem to use a specific quarry. Every Mursi woman who was interviewed pointed to a different direction to show from where their stone originated. In a radius of approximatively 10 km, the stones come from the banks of the river Maki or from the surrounding hills. There seem to be no apparent limits between the territories of raw material supplies between houses or families.

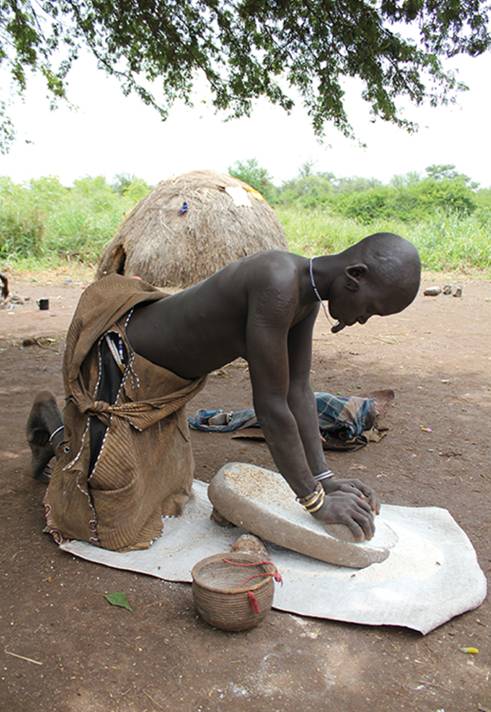

Women first choose a natural, rounded block with the closest dimensions to the anticipated dimensions of the finished tools. This block is then transported by the men of the village. The women shape these blocks only by pecking them (Figure 2). The shaping of the block (into a quern and handstone) may last for several days (between 10 days and a month). Shaping them by pecking will result in the desired final morphology.

Figure 2. A quern waiting to be manufactured and a quern in manufacture. Manufacturing is done by pecking the stone until an appropriate shape is reached.

In Maki, querns and handstone are used daily. Every married woman has at least a quern and a handstone which she uses for different tasks (such as crushing sorghum and corn or milling sorghum, corn, and wheat). Some owners have two to three querns. Some querns are reserved for crushing buna. Other querns and handstones will be used as toys for young girls.

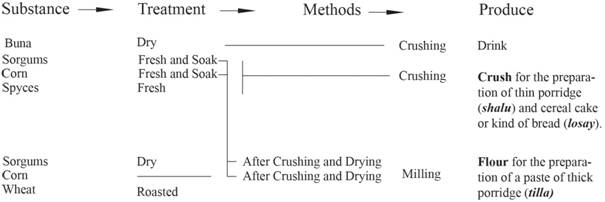

If the weather permits, grinding is done outside of the house (Figure 3). This task allows women to gather and discuss the task. Girls will imitate their mothers and learn how to grind as a game using mud on a quern used for this purpose. Girls begin to learn how to grind between 5 and 10 years old.

It is important to highlight that the Mursi, like others groups in the Omo valley, do not use a pestle and mortar for crushing grains. Instead, they have adapted their techniques and kinetics and use their tools in specific and different ways which allow successful milling and crushing. For example, women adapt their techniques (i.e. their kinetics are different) and, depending on the type of grain that they have selected or the final product that they wish to prepare, they may use a specific part of the handstone or a different handstone. Some handstones are reserved only for crushing grain, others are used only for milling, and some have a double function and are used both for milling and crushing.

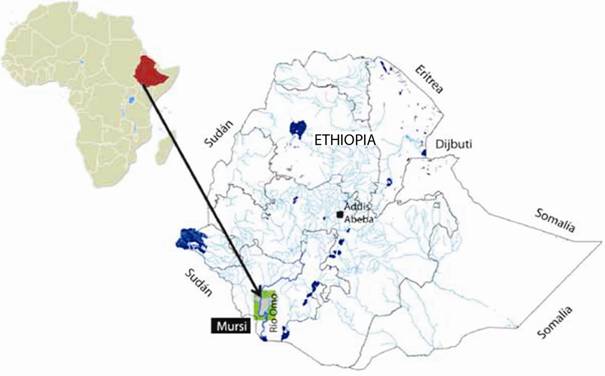

The Mursi use two methods for the treatment of grain on querns: crushing (which involves breaking the grain into pieces) and milling (which turns the grain into powder (flour)). For milling or crushing, the Mursi distinguish a functional variability by the type of action and gesture with a specific part of a handstone or a specific handstone which is involved in the preparation of different foods (Figure 4).

Sorghum is milled into flour when it is dry. The wheat is roasted before it is milled. Dry corn grain is not milled dry. Dry corn grain is soaked in hot water and then it is crushed. If it is not consumed in the form of thin porridge (shalu) or a type of bread (losay), the crushed grain is laid to dry in the sun and only after it has dried it is milled. These three cereals are consumed in the form of a thick porridge (tilla).

In terms of milling itself, the handstone is pushed using the palms of the hands. Every time this action is repeated, the handstone crushes only a small quantity of the handful of grain (while pulling the handstone to the proximal part of the quern, a slight uplift aims to capture new grains in between the working surfaces). For milling, a handful of dry or grilled grain is placed on the proximal portion of the handstone (Figure 5).

Figure 3. Milling outside of the house. Among the Mursi, the “grinding slab” (golu oiné) means the mother, so the “handstone” (golu joiné) represents the baby. The Mursi say that the handstone must rest well on the grinding slab, just as a baby does on its mother’s back.

Figure 4. Type of food preparation: crushing or milling of different substances and the treatment thereof in order to make the final products.

The preparation of several types of grain and condiments involves crushing. The cereals (sorghums and corn) are crushed when they are fresh. If they are dry, they are soaked in hot water prior to being crushed. The crushed sorghums and corn are consumed as thin porridge (shalu) or bread (losay).

Buna is a hot drink prepared from dried coffee skin (exocarpe). A large quantity of the skin of the coffee is crushed and boiled with some spices (garlic and chili). The spices (salt, chili, garlic, etc.), in small quantities, are crushed when they are fresh on a quern with a handstone or a pebble (mouli).

Unlike the action of milling, where the active surface is the ventral part of the handstone, crushing sorghum and corn is done by activation of the dorsal part thereof, using a back and forth motion by rolling the handstone over the material to crush it. In terms of the crushing of buna, the women use the dorsal part of the handstone for crushing or a handstone that is specifically reserved for this function.

Figure 5. Woman milling wheat on a quern; the handstone is pushed using the palms of the hands.

In terms of crushing soaked and fresh cereals and buna, the women place a larger amount of grains on the proximal part. The dorsal part of the handstone is pushed back and forth by rolling its convex surface (Figure 6). The pressure on the handstone for crushing is less significant than that which is used for fine grinding.

Women associate these functions (milling and crushing) with different querns and handstones. Some querns and handstones are reserved for milling while others are used for both milling and crushing cereals. There are also querns and handstones that are reserved especially for crushing buna and spices.

Figure 6. Woman crushing buna by using a handstone that has been pre-selected for this purpose and with a back and forth motion, rolling the handstone over the material to crush it.

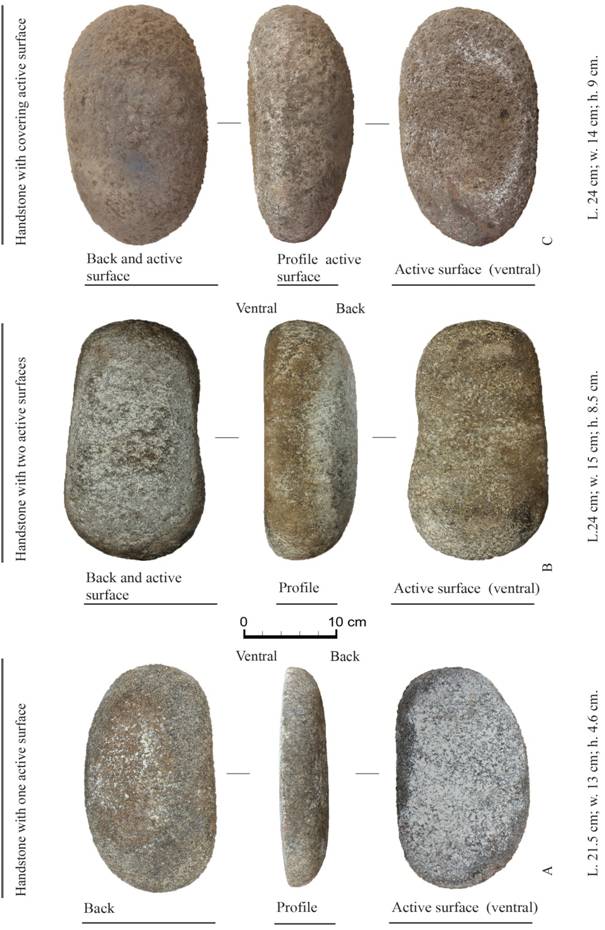

The Mursi of Maki use three types of handstones for milling and crushing cereals and buna (Figure 7).

Figure 7. Types of active surfaces on handstones.

There are handstones that are used only for fine milling, of which only one of their surfaces is used. The handstones used for milling cereals (sorghum, corn, and wheat) have an ovoid form in plan and are semi-circular in section. The active surface for milling (the ventral part) is slightly convex and well-developed, and the back is convex (Figure 7: A).

The handstones that are reserved for milling and crushing the grain (which are used on both sides - the back and ventral parts) have an ovoid form in plan and are semi-circular in section. The active surface for milling is slightly convex, and the back that is used for crushing is convex. The thickness is more significant than that of the handstones, which are specifically reserved for milling (Figure 7: B). The thickness of a handstone plays an important role in the manipulation and motion of the material. It is also a determinative factor in terms of the functions for crushing sorghum and corn. Handstones that have significant thickness would also be used for crushing buna. The thickness depends on the size of the original rock or the intensity of their use.

There is also a handstone that is reserved only for the crushing of buna. The handstone is ovoid in plan and circular in section. This type of handstone does not have a specific active surface. Rather, it is used by pushing and rolling on different areas of the handstone (Figure 7: C). In this case, all of the accessible surfaces of the handstone can be used for the material to be crushed. This type of handstone is not as common as the other types of handstone. Two have been observed and only one was measured and analysed (because I was not permitted to do so by the owner of the other handstone).

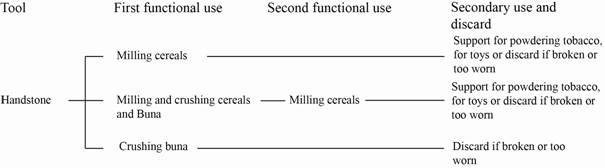

In this study, the functions of the tools have been determined by the owners (Figure 8). The first functional use is understood here as the function for which the tool was initially designed. The second functional use is associated with a change of its function in terms of food preparation. Secondary use is associated with a change of function that is not involved in food preparation (e.g., the tools will be used as toys or for powdering tobacco). Finally, a tool is discarded after extreme use or breakage.

Figure 8. Functional, second functional, and secondary uses of handstones at Maki

At Maki, the first functional use of a handstone is that it can be used for milling cereals and milling and crushing cereals and buna. Lastly, a handstone can be made only for crushing buna. The second functional use of a handstone is observed only in terms of the handstones that are reserved for milling and crushing cereals and buna. Interestingly, after 3-4 years of use for crushing and milling, handstones are no longer considered effective enough for crushing cereals and are only used for milling cereals as a secondary functional use. This change in the use of the handstones is linked to prolonged use and frequent pecking of the active surface, as the pecking reduces the width of the handstone; thereby rendering it non-functional for crushing.

The extent of use and the change of the form (i.e. the morphometry) of the handstones are particularly pertinent criteria, because they allow us to determine the successive functions of these tools. They also allow us to correlate the size of a handstone with its purpose and use with the particular state of grains (dry, soaked, or fresh) in terms of crushing and milling. Dry cereal grains are associated with fine milling. The ventral part of the handstone is used for this purpose. Fresh or soaked cereal grains are associated with the dorsal part of the handstone. Therefore, the handstones show variability in terms of the intrinsic characteristics thereof. The thickness and volume of the handstones offer defining criteria from a functional point of view.

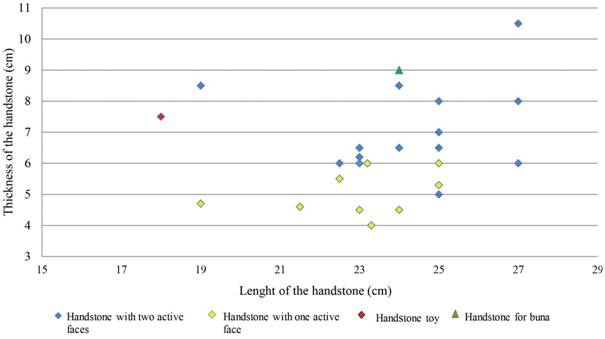

In figure 9, it is shown that the thickness of a handstone determines the function of the tool. The handstones that are reserved for milling cereals (unifacial) have a smaller thickness than those that have been selected for crushing and milling cereals (bifacial). The thickness of the handstones that are reserved for milling (yellow square) does not exceed 6cm. Handstones that have a dual function (blue square), is generally thicker than 6cm. The handstones that have been selected only for crushing buna (green triangle) and toy handstones (red square) are very thick.

Figure 9. Function and morphology of the handstone. Graph showing the importance of the thickness of handstones in terms of determining function. The use on one or two faces also depends on the thickness. The length of the handstones is not a determining factor.

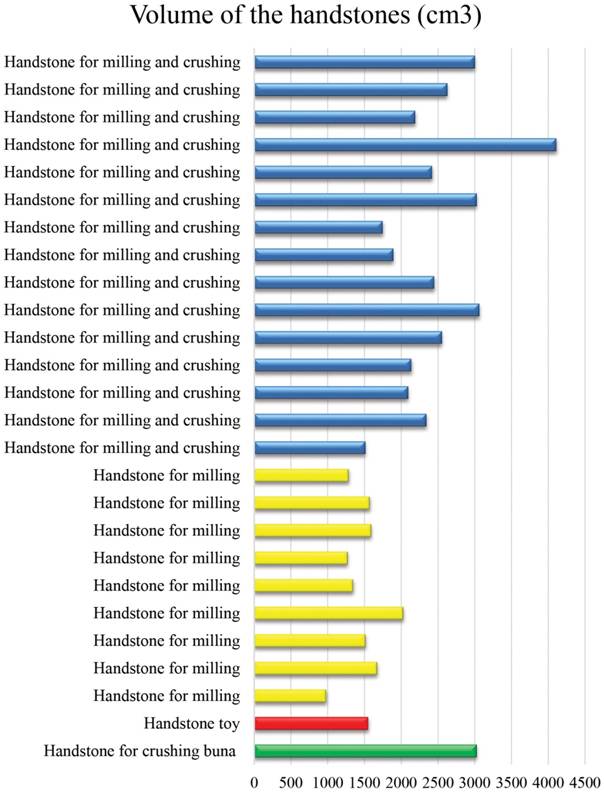

The volume of the handstones is also important in terms of crushing (Figure 10). The handstones that are used for both milling and crushing cereal (in blue) have larger volumes (an average of 2477cm3) and are commonly characterised by a greater thickness than the handstones that are only used for milling. The handstones that are reserved for milling (in yellow) have a smaller volume (with an average of 1472cm3) and are thinner than the handstones that are used for both milling and crushing. The volume of the handstones that are reserved for crushing buna (in green) fit into the category of handstones that are used for both milling and crushing cereals (i.e. their volume is large). The volume of the handstones that are used as toys (in red) resembles the volume of the handstones that are used only for milling (i.e. it is small).

Figure 10. Volumetric characteristics of handstones.

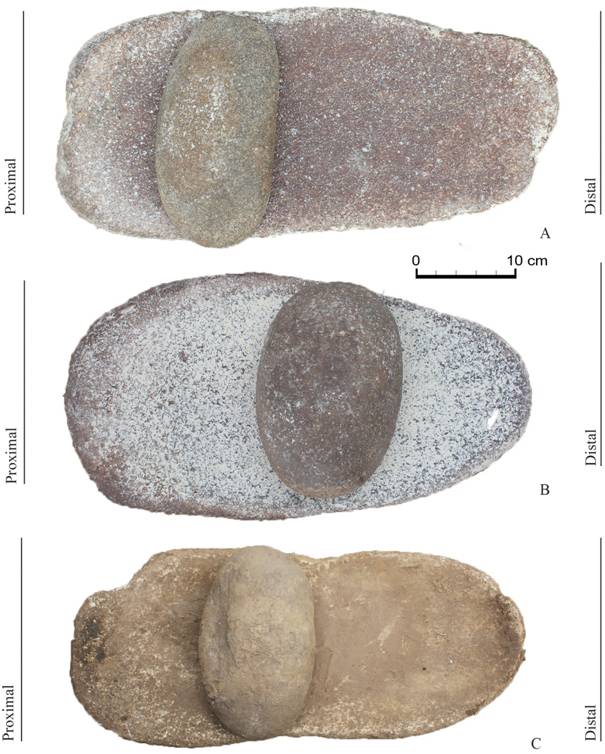

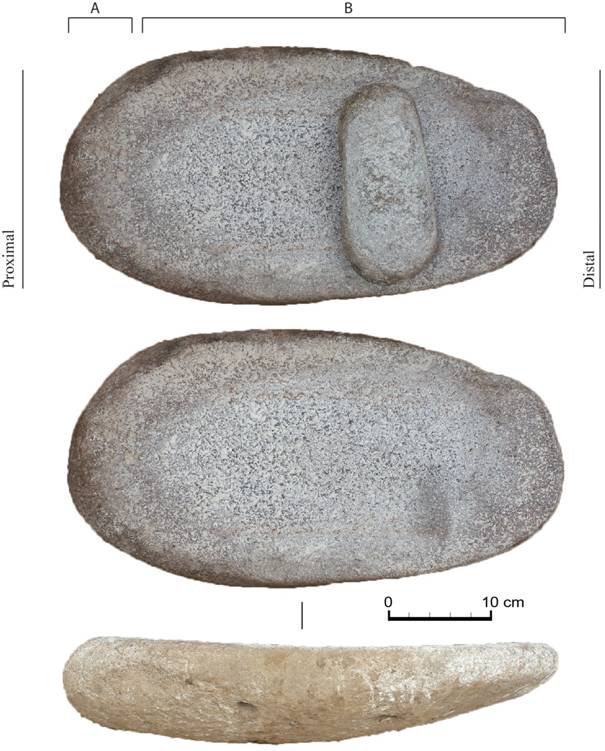

As it is shown in Figure 11, in contrast to the handstones, querns have no morphological characteristics that allow for differentiation between a quern that is used for both crushing and milling cereal, a quern that is used for crushing buna (Figure 11: A), a quern that is only used for milling cereals (Figure 11: B), a quern that is used by children (Figure 11: C), or a quern that is only used for crushing buna. The querns have an ovoid shape in plan and are semi-circular in section.

Figure 11. Querns and handstones used for different functions. A: Quern and handstone used for milling and crushing (wheat, sorghum, and corn). Quern: L. 54 cm; w. 23 cm; h. 8 cm. Handstone: L. 23.3 cm; w. 13.5 cm; h. 4 cm. B: Quern and handstone used for milling cereals (wheat and sorghum). Quern: L. 51 cm; w. 27.5 cm; h. 12.5 cm. Handstone: L. 25 cm; w. 14 cm; h. 7 cm. C: Quern and handstone re-used by a young girl to practice milling and crushing (earth and mud). Quern: L. 44 cm; w. 19 cm; h. 7 cm. Handstone: L. 18.5 cm; w. 11.5 cm; h. 7.5 cm.

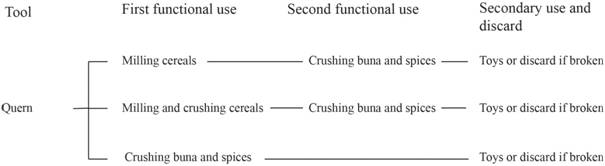

The querns, in the same way as the handstones, have a lifespan involving different uses (Figure 12). The first functional use is the function for which the tool was initially designed. Some querns are used only for milling cereals (dry sorghum, dry crushed corn and wheat). Some other querns are used for both milling and crushing cereals (dry and fresh sorghum, wet corn, and dry crushed corn and wheat). Others are used only for crushing buna and spices. If a woman has only one quern for milling, she will borrow a quern and its handstone for crushing buna from another woman in the compound.

Figure 12. First and second functions, and secondary uses or discarded querns.

The second functional use is associated with a change of a quern’s function in terms of food preparation without a change in the morphology of the tool. Usually, at some point in the prolonged use, all of the querns will develop a second functional use and will only be used for crushing buna and spices. These tools will be re-used because crushing buna and spices leaves residue on the quern, which could add a taste that will be little appreciated if it is mixed with milled or crushed cereals. Here, the querns that are reused for buna do not have morphological (length, width or height) or functional characteristics. No querns that are only used for spices were observed. This second functional use is generally associated with the procurement of a new quern.

The secondary use is associated with a change of function other than food preparation. In the case of secondary use, some handstones and querns are re-used for teaching young girls how to mill and crush. Between the ages of 5 and 10 years old they start imitating their mothers as a game. Lastly, a tool is discarded after extreme use or breakage.

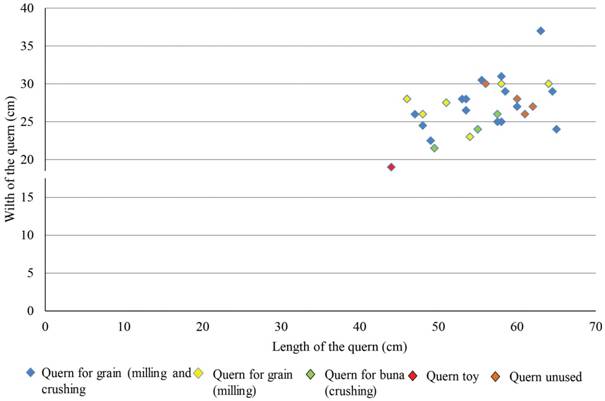

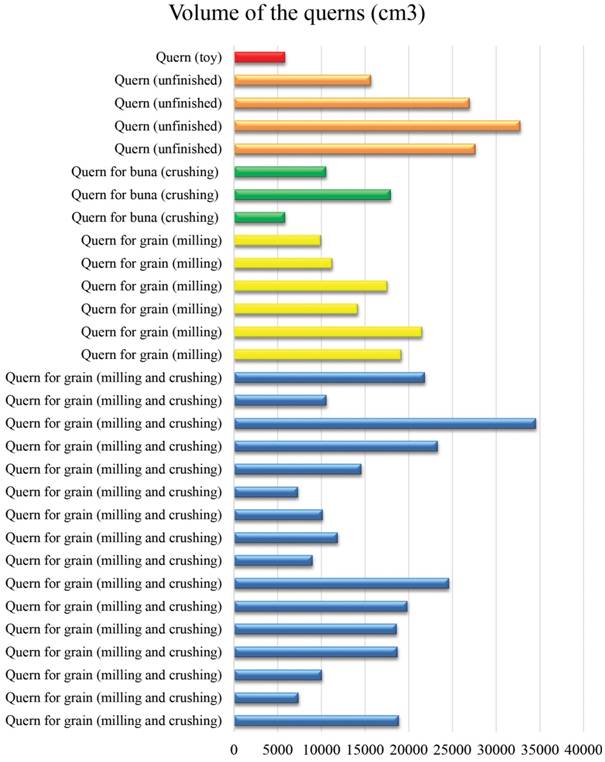

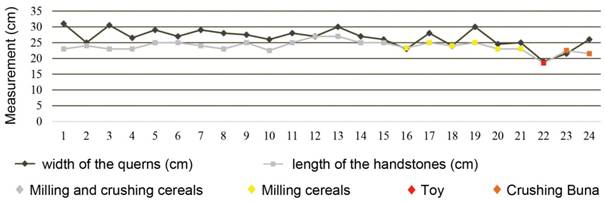

I tried to determine the morphometric characteristics of the querns that could be indicative of their functions of milling or crushing. A histogram showing plots of the morphometric characteristics of all of the querns (Figure 13) shows an overlap between the groups of querns indicating little variability. Querns that are used for milling and crushing cereals (blue square), querns that are used for milling cereals (yellow square), querns that are used for crushing buna (green square), toy querns (red square), and even unfinished querns (orange square) all have similar dimensions. Therefore, it is clear that the functions of the querns do not depend on the morphometric characteristics.

The volumetric characteristics of these querns are not helpful in terms of distinguishing the functions thereof (Figure 14). Querns that are used for milling and crushing or used only for milling cereals have similar volumes. This also applies to the overused querns that have the second functional use of crushing buna and a secondary use (e.g., a toy quern). Again, the functions of the groups of querns (coloured in respect of their functions) overlap.

The deformation of the curvature of the active surface could be related to the morphology of the contact surfaces (i.e. the length of the handstone in relation to the width of the quern), the frequency of the re-picking of the stone, the intensity of use (i.e. the number of users and the number of mouths to feed - the quantity of grain which is ground), and the nature of the raw material.

Figure 13. Functional morphology of the querns. Histogram showing that the functions of the querns are independent to the morphometric characteristics.

For all of the observed pairs of querns and handstones, the length of the handstone versus the width of the quern appears to be, overall, standardised. The handstone generally has a shorter length than the width of the quern (Figure 15).

The width of the querns that are used for milling and crushing is, on average, 3.33cm larger than the length of the handstones. The width of the querns that are used for milling is, on average, 1.96cm larger than the length of the handstones. The width of the quern that is used as a toy is, on average, 0.5cm larger than the length of the handstone. Finally, the width of the quern that is reserved for buna is, on average, 2.5cm larger than the length of the handstone. As a result, the quern is then characterised by a longitudinal and transverse concave curvature and the handstone by a longitudinal and transversal convex curvature.

The proximal part of the quern (the location at which the grain will be ground) is less affected by use-wear than the distal part. The use-wear is more pronounced at 7/8 of the length of the tool (Figure 16). This deformation of the active surface develops over a long period of use. The distal portion of the active surface reaches the edge of the tool. Pressure is concentrated on the distal part of the quern because the worker uses their upper body weight and strength when they push the handstone to this distal part of the quern. In this way, they abrade the quern, which then has to be re-picked. This process results in the thinning of the distal part of the quern.

The daily use of these tools in Maki requires re-picking the tools’ surfaces. According to my interviewees, picking the active surface is undertaken once a week or once every ten days. Picking is specifically undertaken on the active surface of the querns and the handstones that are used for milling and crushing cereal. This has a direct impact on the longevity and the functionality of the tools. The entire active surface of the quern and all of the active surfaces of the handstone are re-picked. This takes between 30 minutes and 1 hour to complete. Re-picking by pecking or hammering must be done regularly, otherwise the surface becomes smooth, at this level of wear, the tool is no longer effective.

Figure 14. Volumetric characteristics of querns.

Figure 15. The width of the quern compared to the length of the paired handstone. Number of the tools: width of the quern / length of the handstone. Tools used for milling and crushing cereals. 1:31/23 ; 2:24/25 ; 3: 30,5/23 ; 4:26,5\23 : 5:29/25 : 6:27/25 : 7:29/24 ; 8:28/23 ; 9:27,5/25 : 10: 26/22,5 ; 11:28/25 ; 12:27/27 ; 13:30/27 ; 14:27/25 ; 15:26/25. Tools used for milling cereals. 16:23/23,3 ; 17:28/25 ; 18:24/24 ; 19:30/25 ; 20:24,5/23 ; 21:25/23. Tools used for toy. 22:19/18,5. Tools used for crushing buna. 23:21,5/22,5 ; 24:24/26.

It is important to stress that the intrinsic properties of the raw material affect the effectiveness of the tool from which it is made. The constituent grains of the rock are worn differently and according to the nature of the material. Unlike the querns and handstones that are made from vesicular basalt (which require very little re-picking) (Dubreuil 2002; personal observation at the Dorze, Ethiopia), querns and handstones that are used for cereals and are made of granite undergo prolonged and intensive use. This causes progressive wear on the working surface, creating polish, reducing the peaks of the topography and eliminating the traces of the original picking. The formation of this polish requires re-picking with the use of a percussion tool, a striker hammer stone (malale). In Maki, re-picking the quern (commonly used for grinding cereals) may be an important factor in terms of determining the length of time for which this tool can be used effectively. Querns that are reserved for buna require re-picking less often than querns that are used for milling cereal.

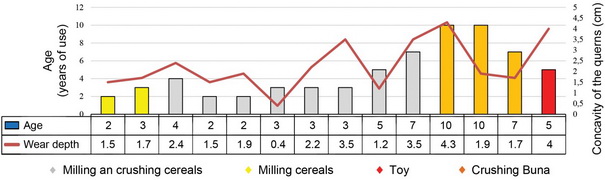

During fieldwork, I was surprised to discover the relatively short duration of use of the milling and crushing tools at Maki. The maximum lifetime of the querns was 10 years, while that of the handstones was five and a half years. This is a very short lifespan compared to grindstones of basalt, vesicular basalt, or quartzite that has been observed in other ethnographical contexts (Table 1).

Frequently re-picking the active surfaces of the tools is one of the major factors that contribute to the limited lifespan of the tools. In Maki, re-picking is done every week or every 10 days to keep the abrasive surface of the tools sharp.

I also verified whether the deformation and the depth of the curvature of the active surfaces of the querns could be correlated with the type of use thereof, the size of the handstone, and the duration of the use of the tool. First, the depth of the active surface was measured from the deepest part of the curvature in relation to the proximal and distal parts of the querns. This was then compared to the length of the handstones, the number of years for which the tools had been used, and their functions (Figure 17).

It can be seen that the depth of the active surface of the querns observed in Maki cannot be directly linked to the type of use or age. This is evident especially in terms of the querns’ uses of milling and crushing. In these cases, the depth of a quern that is three years old can be between 0.4 and 3.5 cm and the depth of a quern that is five years old is 1.2 cm. The same can be observed in terms of the querns that are used for buna (which have experienced between 7 and 10 years of use). This can be the same as a quern that is used for milling that is two years old. According to these observations, there seems to be no direct correlation between the ages of the querns and the depth of the active surfaces.

Figure 16. Typical morphology of a quern: Part A corresponds to the part where the grain is placed for milling. Part B corresponds to the active part of milling or crushing. The proximal part of the quern corresponds to the nearest part of the workers. The distal portion is the most remote part from the workers. Morphology oblong in plan; longitudinal and cross section are semi-circular. The proximal portion is thicker than the distal portion. Dimensions: Quern: L. 58 cm; w. 31 cm; h. 10.5 cm; Handstone: L. 23 cm; w. 11 cm; h. 6 cm.

Table 1. Comparative table showing the average minimum and maximum ages of stone tools that are used in Central America and Africa.

|

Area |

Min. years of use |

Max. years of use |

Geology |

References |

|

Maya Highlands (grinding slab, metates) |

5 |

80 |

vesicular basalt |

Hayden 1987: 194 |

|

Maya Highlands (handstone, manos) |

3 |

100 |

vesicular basalt |

Hayden 1987: 194 |

|

Guatemala (grinding slab, metates) |

10 |

100 |

vesicular basalt |

Horsfall 1987: 343 |

|

Guatemala (handstone, manos) |

3 |

100 |

vesicular basalt |

Horsfall 1987: 343 |

|

Ghana (grinding slab) |

25 |

45 |

quartzite |

Delgado-Raack & Risch 2009: 10 |

|

Ghana (handstone) |

17 |

25 |

quartzite |

Delgado-Raack & Risch 2009: 10 |

|

Ethiopia, Dorze (quern) |

10 |

80 |

vesicular basalt |

Robitaille (current paper) |

|

Ethiopia, Mursi (quern) |

7 |

10 |

granite |

Robitaille (current paper) |

|

Ethiopia, Mursi (handstone) |

4 |

5 |

granite |

Robitaille (current paper) |

Figure 17. Comparison between the years of the use of the querns with the depth of the wear on their active surfaces. No correlation is found between the duration of use and the depth of the active surfaces, irrespective of the type of food that is processed.

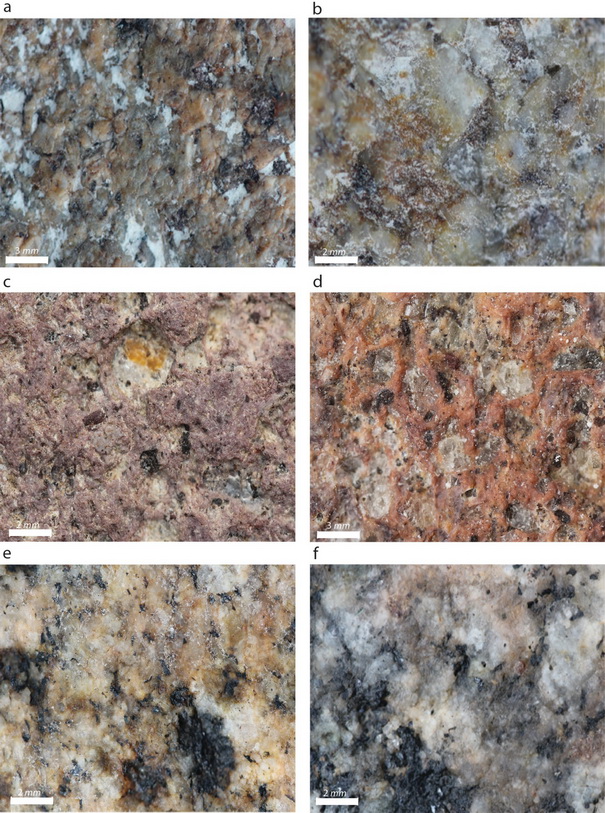

The observation and systematic description of use-wear has allowed for the identification of recurring patterns and links in terms of use-wear and the kinematics and associated activities of ethnographic tools. This research briefly presents the different types of use-wear that are associated with different treatments of cereals, including considerations about the different kinds of handstone manipulation during use (kinematics).

This study takes into account the micro-topography and the state of the stone grains. This analysis of the active surface of the tools focuses on a complex combination of use-wear traces on the micro-surface relief (micro-topography) and that of the individual grains of stone.

Changes in micro-topography are characterised based on the material that is crushed or milled. The most relevant characteristics that have been identified relate to the type of alteration that is affecting the stone grains (fracture, edge rounding, levelling, polishing, linear traces, striation) and the magnitude of this alteration (affecting the top and edge of the grain, and wear developing in the interstices of the micro-relief). These characteristics are the most important elements for defining the nature of the contact surfaces of the tools. Adams, et al. (2009: pp.49-53) described the macroscopic and low magnification traces, as presented in the following table (Table 2).

Table 2. Summary of descriptions of the macroscopic and low magnification traces as defined by Adams et al. (2009). Microwear traces observed on groundstone tools.

|

Trace |

Description |

|

Grain fracture or microfracture |

Including scars, step fractures, flake removals, and crushing or breakage of the crystals. Microfracture damage tends to be particularly common on pecked surfaces, and often remains frequent throughout the first stages of tool use (especially during the first hour of use after pecking) (Adams et al. 2009: 53). |

|

Edge rounding |

Unlike microfracture, edge rounding is associated with contact with soft, pliable matter that penetrates into the interstices. Edge rounding can be more or less extensive across the surface of the grain (Adams et al. 2009: 53). |

|

Polish or shine |

Polish typically describes a shiny surface. Grace (1989:38) defined it “as a visible alteration of the natural surface that increases its reflectivity”. Polish is linked to another wear process called ‘levelling’ which is subsequently described (Adams et al. 2009: 50). |

|

Levelling |

Levelling corresponds to a reduction of the volume of the grains by the selective attrition of their summit. This process can create a facet on the top of the grain. Levelling can affect individual grains or a larger area, resulting in a zone where grains lack interstices between them. The morphology in profile and roughness of the levelled surface are important parameters to consider when characterizing the type of levelling (Adams et al. 2009: 53). |

|

Grain extraction |

The removal of grains from the matrix commonly occurs on most ground stone tools. As with microfracture, the removal of grains tends to be particularly frequent in early stages of utilization. The frequency of grain removal appears to be strongly correlated with the cohesion of the raw material and the hardness of the minerals (Adams et al. 2009: 53). |

|

Linear traces - striation and scratches |

Striations are more likely to be seen macroscopically on fine-grained types of rock and on flat, even surfaces. Abrasive tracks or grooves were, however, typically associated with the processing of abrasive or hard matter (ochre, stone, and shell). It should be noted that striations and abrasive tracks may only be identifiable at certain scales of observation. Likewise, the type of striation seems to vary as a function of the scale of observation (Adams et al. 2009: 49). |

Every trace is the result of specific use-wear mechanisms. Nevertheless, one must take into account that, in dynamic or successive activities, use-wear patterns may fade or appear to be combined. The evolution of the stigma in the use of multi-functional tools makes the interpretation of use traces complex. My interviews with various users have enabled me to isolate certain tools for the determination of the types of grain treatment for this functional analysis.

Seven different types of use-wear which can be clearly identified within the assemblage from the Mursi and were recurrent are examined here. These were caused by crushing or milling wheat, sorghum, corn, buna, spices, and a combination of some of these materials or dirt (Table 3). For each of the registered uses, descriptions of surfaces and macro-pictures (Canon Rebel T2i with a macro-lens of EFS 60mm) are provided.

Table 3. Use-wear traces caused on granite querns and handstones depending on the material that is processed and its condition. Abbreviations: x - Stigmas associated with a different used; (x) - Some of this use wear is seen on the active surface (not generalize); (x1) - Leveling of the height topography from manipulation; (x2) - Polish from manipulation.

|

Activity |

Milling |

Crushing |

Crushing or milling |

Manipulation |

|||||

|

Buna, manipulation |

Back of a handstone reserved for milling |

||||||||

|

Id change Material |

Wheat |

Sorghom |

Sorghom |

Corn |

Buna |

Spices |

Dirt |

|

|

|

Condition |

grilled |

dry |

fresh |

fresh or soaked |

dry |

fresh |

dry-wet |

dry |

|

|

Levelling |

x |

x |

|

|

|

|

|

|

|

|

Striations |

|

|

|

|

|

|

x |

|

|

|

Scratches |

|

(x) |

|

|

|

|

x |

|

|

|

Polish or sheen |

x |

|

|

|

|

|

|

|

(x2) |

|

Grain fractures |

|

|

x |

x |

x |

x |

x |

x |

|

|

Grain extraction |

|

|

x |

|

x |

|

x |

x |

|

|

Edge rounding |

x |

(x) |

|

x |

|

x |

|

(x1) |

(x1) |

After extensive use, the smooth or completely smooth surfaces of the tools present levelling and rounding grains. After pecking or hammering, the active surfaces will be characterised by grain fractures and extraction of grain. Before using the newly pecked tools, the women pass the handstone on the quern a couple of times in order to eliminate the particles of material which do not detach easily and may cause contamination of the product that will be milled or crushed.

Regarding kinematics, in terms of milling cereals the ventral part of the handstone is used in percussion posée diffuse (Leroi-Gourhan 1971:58-59). In terms of crushing cereals, the back of the handstone is used in percussion posée in a back and forth motion while rolling the handstone over the material.

After the first use of a quern and handstone for milling wheat (i.e. the first use after pecking), the surfaces of the grain are characterised by edge rounding. Only the tops of the grains are affected at this point. It is only after longer use that the general stone grain appears with complete edge rounding. At this level of use, the surface looks glossy or polished (Figure 18: A). After prolonged use, there is the surface of the grain is levelled. The interstices are then connected. At this stage, it will be necessary to pick the surface again for good operation. The same characteristics are visible on the active surfaces of the handstones (Figure 18: B).

In terms of milling dry sorghum, the active surface of the tools are characterised by a slight flattening of the grain of the rock (Figure 18: C). Some grains present edge rounding, but not as pronounced as they are when wheat has been milled. The presence of scratches (lines thinner than those of striation) are present on some grains. No polish is observed on the tools.

Crushing fresh sorghum is done by pushing and rolling the dorsal part of the handstone. This creates light levelling of the active surfaces of the quern and the handstone. The grains are characterised by fracture accompanied by some extractions (Figure 18: D). The angle of the edges of the grains bear a matte appearance. No polish is visible after crushing sorghum.

Crushing fresh corn is done on a handstone that was previously used for crushing sorghum. The corn is crushed by using the dorsal surface of the handstone in a back and forth motion. The active surface of the handstone (which is reserved for crushing maize and sorghum) features characteristic traces of crushed, tempered material and smooth edge-rounding that covers the fractured grain of the active surface because it was previously used for crushing sorghum. The high elevation and the interstices seem to be all affected by this type of use (Figure 18: E).

Interestingly, this use-wear is similar to the back of the handstone that is reserved for milling. The manipulation of the non-active part of the handstone (the part that is held by hand) is characterised by edge-rounding the high elevation, which penetrates into the interstices on an unlevelled surface (Figure 18: F). Some of these handstones bear slight polish created by manipulation.

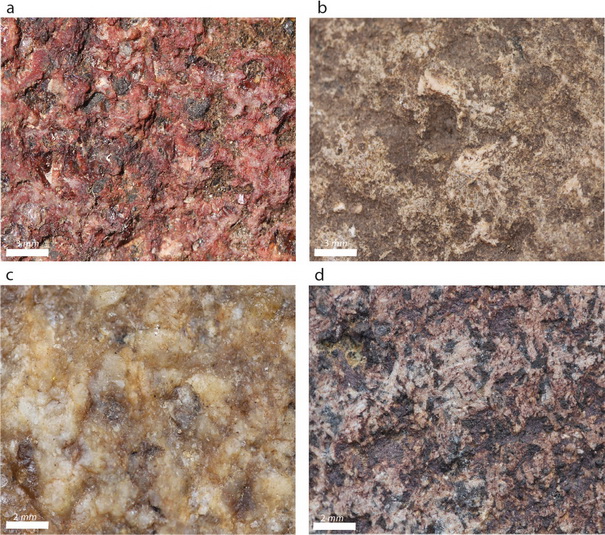

Figure 18. Macro-photographs (x10 and x15 magnification) of the active surfaces of handstones and querns showing different use-wear. a) Milling wheat (surface of a handstone). Flour is still visible in the interstices. b) Milling wheat (surface of a quern). Flour is still visible in the interstices. c) Milling dry sorghum (surface of a quern). Only the high topography is affected in this picture. d) Crushing fresh sorghum (surface of a quern). Fracture and extraction of grain. e) Crushing corn and sorghum (active surface from the back of a handstone, last used for crushing corn). f) Manipulation (surface of the back of a handstone). Use for milling cereals. (Scale bars. a. 3 mm, b. 2 mm, c. 2 mm, d. 3 mm, e. 2 mm, f. 2 mm.)

The active surface of the quern that is used for crushing buna is rather rough. The stone grains of the active surface appear fractured and angular. Abrasive wear is visible and there is no glossy zone (Figure 19: A). Unlike the quern that is used for cereals, the grains of the rock of the querns for buna remain sharp after prolonged use.

Regarding the paired specialised handstone, a combination of characteristics is visible. The active surface of the handstone presents high (but rounded) topography (Figure 19: B). This is because of the kind of manipulation during use (i.e. rolling the handstone), which renders the fractured grain into rounded asperities. This is not apparent on the active surfaces of the querns that are used for buna, because they are not manipulated during use.

Crushing spices with the use of a handstone is done on a quern that is reserved for buna. The use-wear on such handstones and querns is characterised by edge-rounding on the fractured grains, which is associated with the crushing of buna (Figure 19: C).

Crushing spices on a quern that is used for buna will cause the elimination of the angle of the grain of the active surface. Only the central part of the active surface will be affected by this function. Therefore, the surface of the quern which surrounds the active surface is characterised by some fracture and extraction of grain and concentration of edge-rounding in the localised area (other than the active surface) on which the spice was crushed.

The active surface of a toy quern and handstone can be characterised by some deformation of grains and longitudinal striation on the quern and transversal striation on the handstone. The striation is caused by the friction of the abrasive particles that are present in the mud, which the young girls crush or mill (Figure 19: D).

The macro-analysis of the active surfaces of tools that are used for milling and crushing has enabled differentiation among the tools that are necessary for crushing buna, milling and crushing sorghum and corn, milling wheat, and for milling or crushing dirt by children. Here, I presented the most recurrent traces of use that I observed, namely the seven (clearly defined) types mentioned in Section 4 and also presented in Table 3 herein.

Many elements of trace formation can be seen in this preliminary study of the milling and crushing tools of the Mursi of Maki. The difference in the wear patterns on querns and handstones can be determined by several factors, including: kinetics (i.e. the exerted pressure and movement of the handstone on the material that is being processed); the material that is processed; the condition of the material that is processed (dry, roasted, soaked, or fresh); and the amount of the crushed material on the quern. All of these factors appear to influence the formation of different type of traces on the active surface of these granite tools.

To summarise the effect of these factors: the pressure on a handstone and the small amount of wheat or sorghum on a quern for milling seems to be an important factor that causes the edge-rounding and levelling of the stone grain on the active surface.

The use of a handstone for crushing a large quantity of material on a quern does not cause the levelling of the stone grain on the active surface of the quern or of the handstone. The light pressure of the handstone that is used for crushing affects the high topography of the stone grain and the interstices of both tools.

Figure 19. Macro-photographs (x10 and x15 magnification) of the active surfaces of handstones and querns showing different use-wear. a) Crushing buna (quern reserved for buna). Debris remains in the interstices of the active surface. b) Crushing buna and manipulation (handstone reserved for buna). Debris is still visible in the interstices. c) Crushing spices with a handstone on a quern reserved for buna and spices. d) Crushing and milling dirt (surface of a quern). (Scale bars: a. 3 mm, b. 3 mm, c. 2 mm, d. 2 mm.)

The main characteristics of an active surface that is used for crushing sorghum and buna are the fracture and extraction of grain. Because of the nature of the dry material, the edge of the grain will stay sharp. Edge-rounding of the grain (which also affects the interstices) is noticeable on the tools that are used for crushing fresh corn.

It is important to highlight the difficulty of ascertaining the difference between the back of the handstone that is used for crushing and the back of the handstone that is used for milling grain. At this level of functional analysis, the same use-wear traces can be seen. The sole differentiation that can be made is that, on the back of the handstone that is used for milling, more pronounced manual polishing can be noticed in the area in which the hands are placed for the act of milling.

It is the state of the active surfaces which provides the first of the criteria necessary for the definition of a tool from a functional perspective. The macro-observation of the active surfaces of tools for milling and crushing enables us to differentiate between querns that are necessary for crushing buna, those that are used for grain, and those that are used for crushing sorghum and corn, those that are used for milling sorghum and wheat, and toy querns.

This case study, based on a typo-functional analysis of material from Maki, Ethiopia, allows for the identification of a wide range of functions of querns and handstones. Through the identification of these functions, this study shows that tools in Maki may be specialised or multi-functional. The handstones and querns are adjusted to also serve as pestles and mortars. They are used both for milling and crushing and they have a cycle of use.

In Maki, a functional variability of the different categories of milling and crushing handstones has been observed, involving different techniques and preparation of different foods. It seems that the morphometry and the degree of utilisation of these handstones can be a functional criteria since the function(s) (milling or crushing) can be related to the volume and thickness. Furthermore, a change in the morphometry and the function(s) of the handstone is apparent because of continual use, which eventually results in a change in the thickness of the tool. A handstone with a small thickness will be reserved for milling and a handstone with a large thickness will be used for crushing. The handstone that is reserved only for crushing buna is of a more rounded shape and it does not have a very developed active surface. The back of a handstone, which is characterised by a large volume and thickness, is used for the specific function of crushing fresh or soaked grain. In contrast, in terms of milling, the grain must be dry; and the ventral surface of the handstone is used in this case. These morphometric criteria are particularly important since they allow the determination of the successive functions of handstones. Thus, the volumes of the stones and the states of the work surfaces allow the identification of the function(s) of a handstone.

In contrast, the morphometric data about the querns does not allow a functional differentiation between crushing and milling. Frequent re-picking (necessitated by the nature of the raw material and the kind of cereals that are processed) could be a determinant factor that affects the short lifespan of this tool. The second functional use of querns is associated with economic management of the raw material. This second functional use is the crushing of buna. Here, the querns that are re-used for buna do not have morphological or functional characteristics. In terms of crushing the buna, re-picking the quern and the handstone is much less frequent. Re-using these tools for this purpose prolongs, therefore, the active life of a quern.

Morphometric characteristics and use-wear evidence in combination with ethnographic data have been shown here to produce important results regarding the function of macro-lithic (ground stone) tools and can be used for a comparative basis in archaeological analysis.

I would like to thank my guide, O. Rege, for his interpretation from Mursi to English and A. McCaig for her help with English language terminology. Any errors remain mine.

Adams, J. L. 1999, Refocusing the role of food-grinding tools as correlates for subsistence strategies in the U.S Southwest. American Antiquity, 64(3): 475-498. doi:10.1017/S0003598X00084921

Adams, J.L., Delgado, S., Dubreuil, L., Hamon, C., Plisson, H., & Risch, R. 2009, Functional analysis of macro-lithic arthefacts: a focus on working surfaces. In: Non-flint Raw Material Use in Prehistory. Vol. II, (Sternke, F., Eigelang, L., & Costa, L-J., Eds.), BAR International Series Vol. 1939, Archaeopress, Oxford: p. 43-66.

Baudais, D., & Lundström-Baudais, K. 2002, Enquête ethnoarchéologique dans un village du nord-ouest du Népal: les instruments de mouture et de broyage. In: Moudre et Broyer, l’Interprétation Fonctionnelle des Outils de Mouture et de Broyage dans la Préhistoire et l’Antiquité. Tome I: Méthodes, (Procopiou, H. & Treuil, R., Eds.), Actes de la Table Ronde Internationale de Clermont-Ferrand, 30 nov.-2 déc. 1995. Comité des Travaux Historiques et Scientifiques, Paris: p. 155-180. (in French) (“Ethnoarchaeological investigation in a village in northwest Nepal: Milling and grinding tools”)

Beaune, S. de. 2000, Pour une Archéologie du Geste. Broyer, Moudre, Piler, des Premiers Chasseurs aux Premiers Agriculteurs. C.N.R.S., Centre national de la recherche scientifique, Paris, 235 p. (in French) (“For an archaeology of the gesture. Grinding, milling, crushing, from the first hunters to the first farmers”)

David, N. 1998, The ethnoarcheology of grinding at Sukur, Adamawa state, Nigeria. African Review, 1(1): 13-63.

Delgado-Raack, S. 2008, Prácticas económicas y gestión social de recursos (macro)líticos en la Prehistoria reciente (III-I milenios aC) del Mediterráneo Occidental. Unpublished Ph.D. thesis, Universitat Autònoma de Barcelona, Barcelona, 694 p. (in Spanish) (“Economic practices and social resource management of (macro)lythic in recent prehistory (3rd-1st millennia BC) of the Western Mediterranean”)

Delgado-Raack, S. & Risch, R. 2009, Towards a systematic analysis of grain processing technologies. In: Recent functional studies on non-flint stone tools: methodological improvements and archaeological inferences, (de Araújo Igreja, M., Clemente Conte, I. Eds.), Proceedings of the Workshop. LAMPEA 23-25 May 2008, Laboratoire Méditerranéen de Préhistoire Europe-Afrique, Lisboa: p. 1-20.

Dubreuil, L. 2002, Etude Fonctionnelle des Outils de Broyage Natoufiens: Nouvelles Perspectives sur l'Emergence de l'Agriculture au Proche-Orient. Unpublished Ph.D. thesis, Préhistoire et géologie du quaternaire, Université de Bordeaux I, Bordeaux, 471 p. (in French) (“Functional study of Natufian grinding tools: New perspectives on the emergence of agriculture in the Near East”)

Fullagar, R., & Field, J. 1997, Pleistocene seed-grinding implements from the Australian arid zone. Antiquity, 71: 300-307. doi:10.2307/2694147

Gelbert, A. 2002, Evolution du matériel de broyage de la communauté Dii de Djaba (Nord Cameroun) durant les deux derniers siècles: études ethnoarchéologique et archéologique. In: Actes du Colloque Méga-Tchad: Ressources Vivrières et Choix Alimentaires dans le Bassin du Lac Tchad. 20-22 novembre 2002, Université de Genève, IRD Éditions, Institut de recherche pour le développement et Prodig Édition, Centre National de la Recherche Scientifique, Paris: p. 319-347. (in French) (“Evolution of the grinding tools of the Dii community Djaba (North Cameroon) during the last two centuries: archaeological and ethno-archaeological studies”)

González, J. E., & Ibáñez, J. J. 2002, The use of pebbles in Eastern Vizcaya between 12000 and 10000 B.P. In: Moudre et Broyer, l’Interprétation Fonctionnelle des Outils de Mouture et de Broyage dans la Préhistoire et l’Antiquité. Tome I: Méthodes, (Procopiou, H. & Treuil, R., Eds.), Actes de la Table Ronde internationale de Clermont-Ferrand, 30 nov.-2 déc. 1995. Comité des Travaux Historiques et Scientifiques (CTHS), Paris: p. 69-80.

Hayden, B. 1987, Lithic Studies Among the Contemporary Highland Maya. University of Arizona Press, Arizona, 387 p.

Hamon, C., & Plisson, H. 2008, Which analytical framework for the functional analysis of grinding stones? The blind test contribution. In: Prehistoric Technology 40 Yearslater: Functional Studies and the Russian Legacy, (Longo, L., & Skakum, N., Eds.), Museo Civico di Verona & Università degli Studi di Verona, Verona. BAR International Series Vol. 1783, Archaeopress, Oxford: p. 29-38.

Hoersfall, G.A. 1987, Design theory and grinding stones. In Lithic Studies Among the Contemporary Highland Maya, (Hayden, B. Ed.), University of Arizona Press, Arizona: p. 323‐377.

Leroi-Gourhan, A. 1971, Évolution et Techniques: L’Homme et la Matière. Éditions Albin Michel, Paris, 348 p. (in French) (“Evolution and techniques. The man and the matter”)

Mauldin, R. P. 1993, The relationship between ground-stone and agricultural intensification in Western New Mexico. Kiva, 58: 317-330. doi:10.1080/00231940.1993.11758212

Risch, R. 2002, Recursos naturales, medios de producción y explotación social. Un análisis económico de la industria lítica de Fuente Alamo (Almería), 2250-1400 antes de nuestra era. Verlag Philipp von Zabern, Mainz am Rhein. p. 237-278. (in Spanish) (“Natural resources, means of production and social exploitation. An economic analysis of the lithic industry in Fuente Alamo (Almería), 2250-1400 BCE”)

Rodríguez, J. R. 2013, La molienda en Mesoamérica, formas, funciones, usos y manufactura de los instrumentos. Un estudio etnoarqueológico en México. Unpublished Ph.D thesis, Universitat de Barcelona, 573 p. (in Spanish) (“Milling in Mesoamerica, forms, functions, uses and manifacture of the instruments. An ethnoarchaeological study in Mexico”)

Roux, V. 1986, Le Matériel de Broyage. Etude Ethnoarchéologique à Tichitt (R.I.) Mauritanie. Mémoire Vol. 58. Edition Recherches sur les Civilisations, Paris, 111 p. (in French) (“The grinding equipment. Ethnoarchaeological Study in Tichitt (R.I ) Mauritania”)

Salazar, J., Robitaille, J., & Díez, A., 2012, La industria lítica mursi en el valle del Mago (Etiopía). Archivo de Prehistoria Levantina, 29: 379-396. (in Spanish) (The Mursi lithic industry in the valley of Mago, Ethiopia)

Searcy, M. T. 2011, The Life-Giving Stone: Ethnoarchaeology of Maya Metates. University of Arizona Press, Tucson. 192 p.

Sigaut, F. 1991, Un couteau ne sert pas à couper mais en coupant. Structure, fonctionnement et fonction dans l'analyse des objets. In: 25 ans d’Etudes Technologiques en Préhistoire. ERA 28 du CRA du CNRS, Bilan et Perspectives, Actes des XIèmes Rencontres Internationales d’Archéologie et d’Histoire d’Antibes, 18-19-20 octobre 1990, Juan-les-Pins, éditions APDCA, p. 21-34. (in French) (“A knife is not used to cut but for cutting. Structure, operation and function in the analysis of objects”)

Turton, D. 1973, The Social Organisation of the Mursi, a Pastoral Tribe of the Lower Omo Valley, Southwestern Ethiopia. Unpublished Ph.D. thesis, University of London, London, 425 p.

Wright, K. 1994, Ground-stone tools and hunter-gatherer subsistence in Southwest Asia: implications for the transition to farming. American Antiquity, 59: 238-262. doi:10.2307/281929

Wright, K. 2000, The social origins of cooking and dining in early villages of western Asia. Proceedings of the Prehistoric Society, 66: 89-121. doi:10.1017/S0079497X0000178X